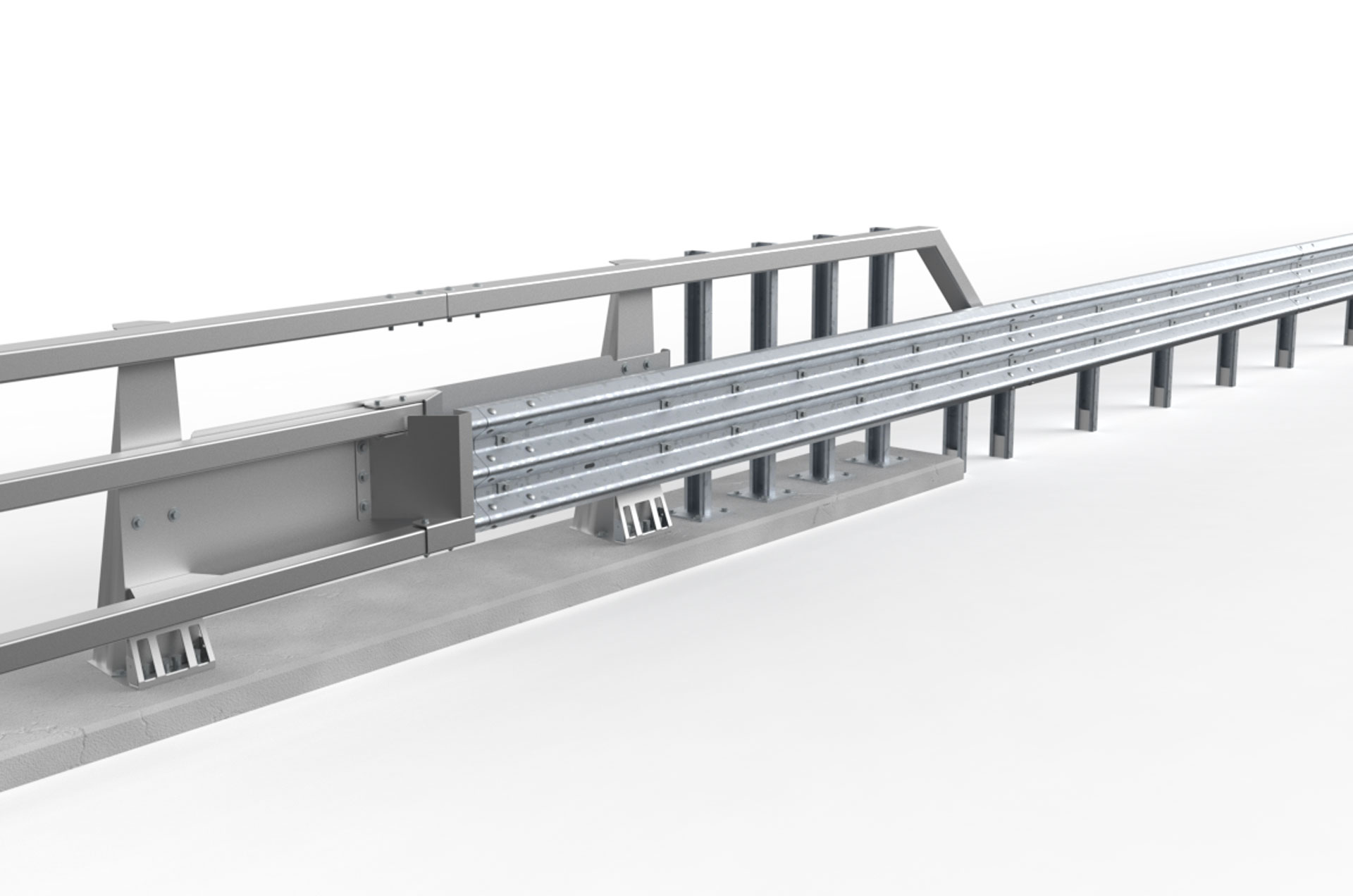

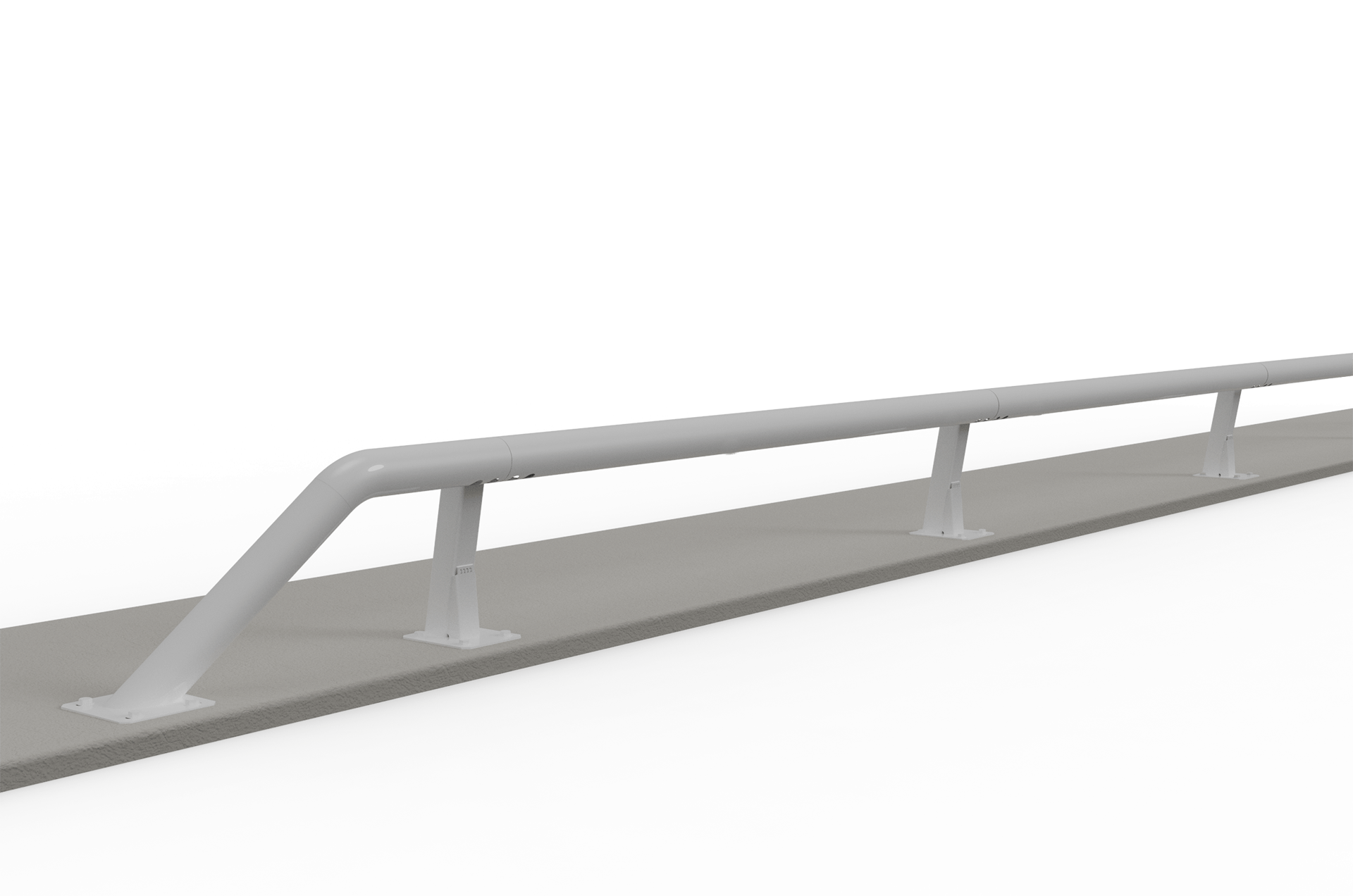

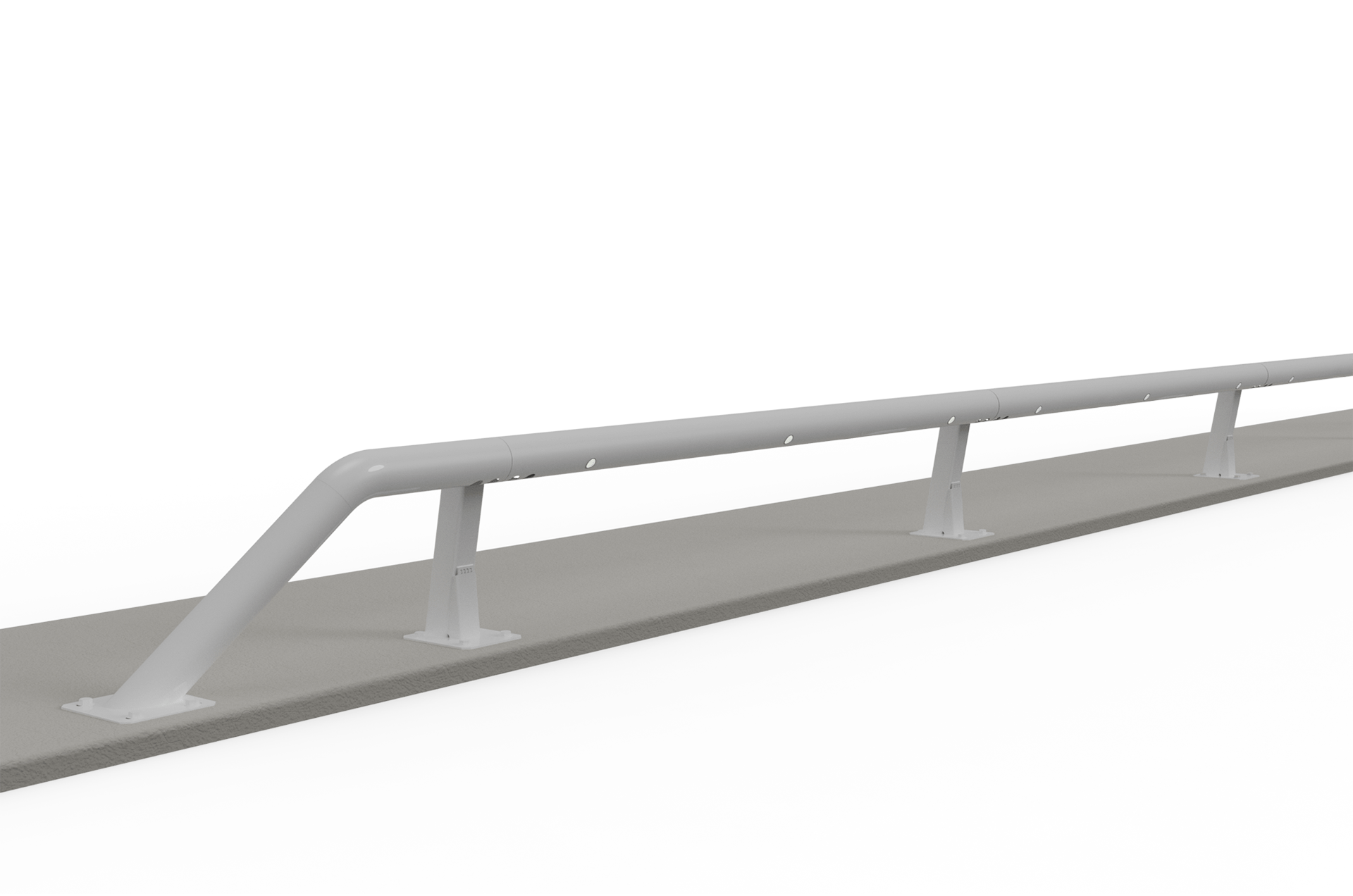

META13® bridge parapet

The META13 steel parapet is a vehicle containment system designed for installation on the edges of bridge decks, grade-separated crossings, supporting wall crowns, and similar works. The device is approved according to Standard UNE EN 1317 Parts 1 and 2 that, together with compliance with Part 5 regarding production control, has obtained the CE marking.

| Reference: | 6247 |

|---|---|

| Weight: | 61 Kg/m |

| Documentation: | |

| Availability: | In stock |

Technical Information

System Characterization

- Containment Level: H2

- Working Width Class: W2

- Working Width (m): 0.8

- Vehicle Intrusion Class: VI2

- Vehicle Intrusion (m): 0.7

- Dynamic Deflection (m): 0.6

- ASI: B

- Tested Length (m): 57.5

- Weight (kg/m): 61

Geometric Characteristics

- Height (mm): 1235

- Distance Between Posts (mm): 2500

- Modulation (m): 7.5

- Curb on Pavement (mm): 120

Installation

- Is Suitable for existing structures:

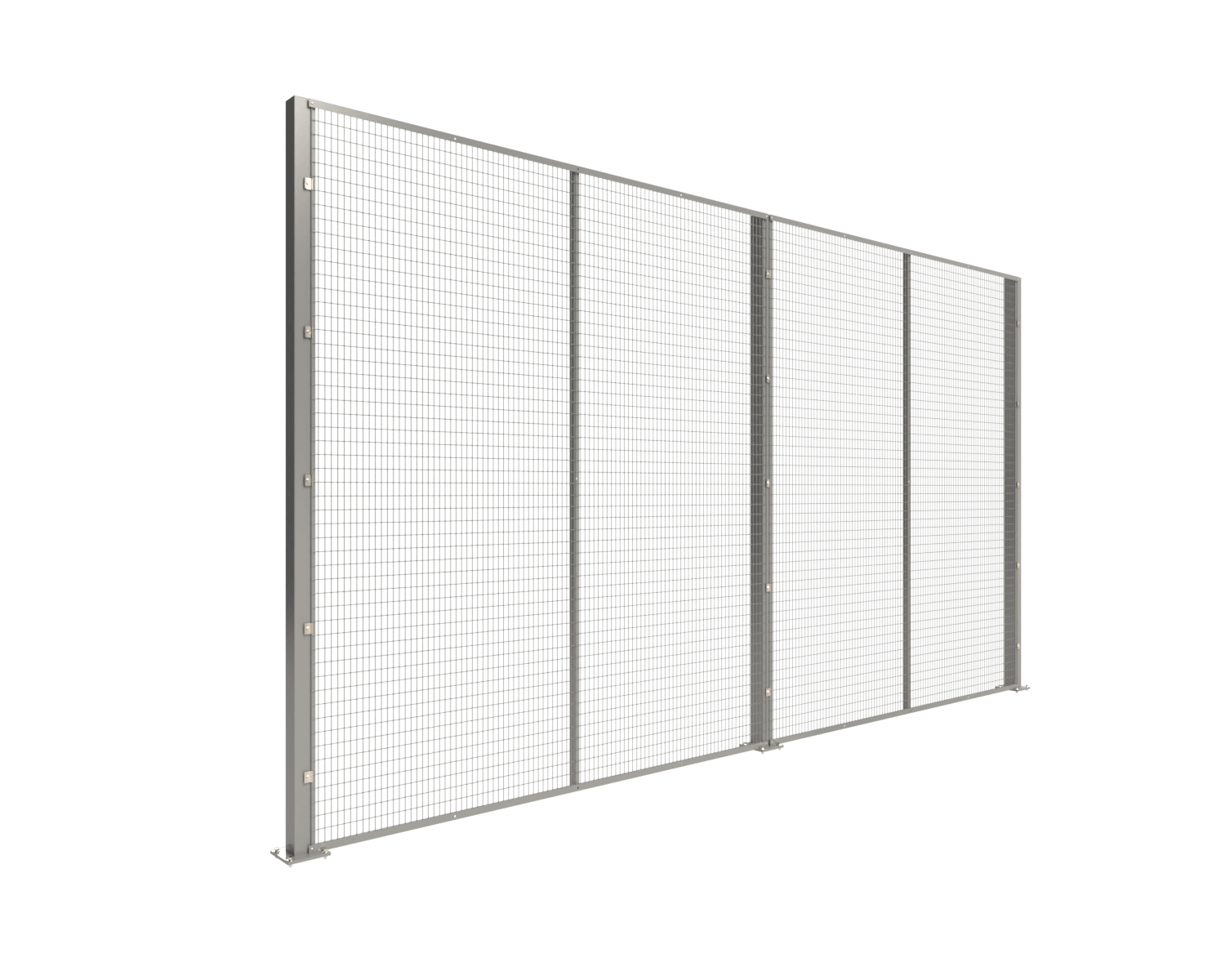

- Optional equipment: Grille

- Installation conditions: Anchored to concrete

The CE marking of the META13 steel parapet shows excellent parameters obtained in thorough, full-scale crash tests performed in an accredited laboratory.

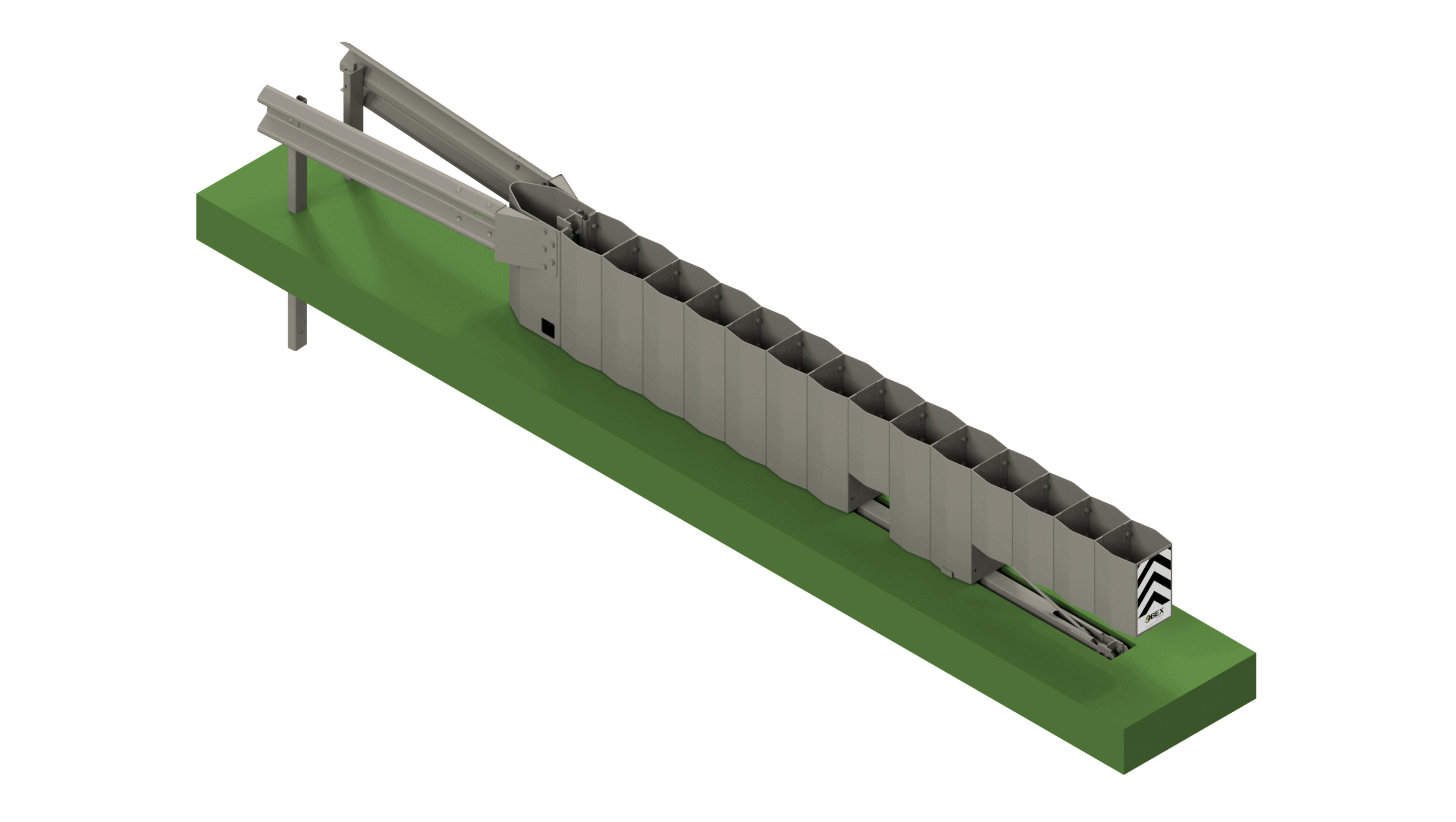

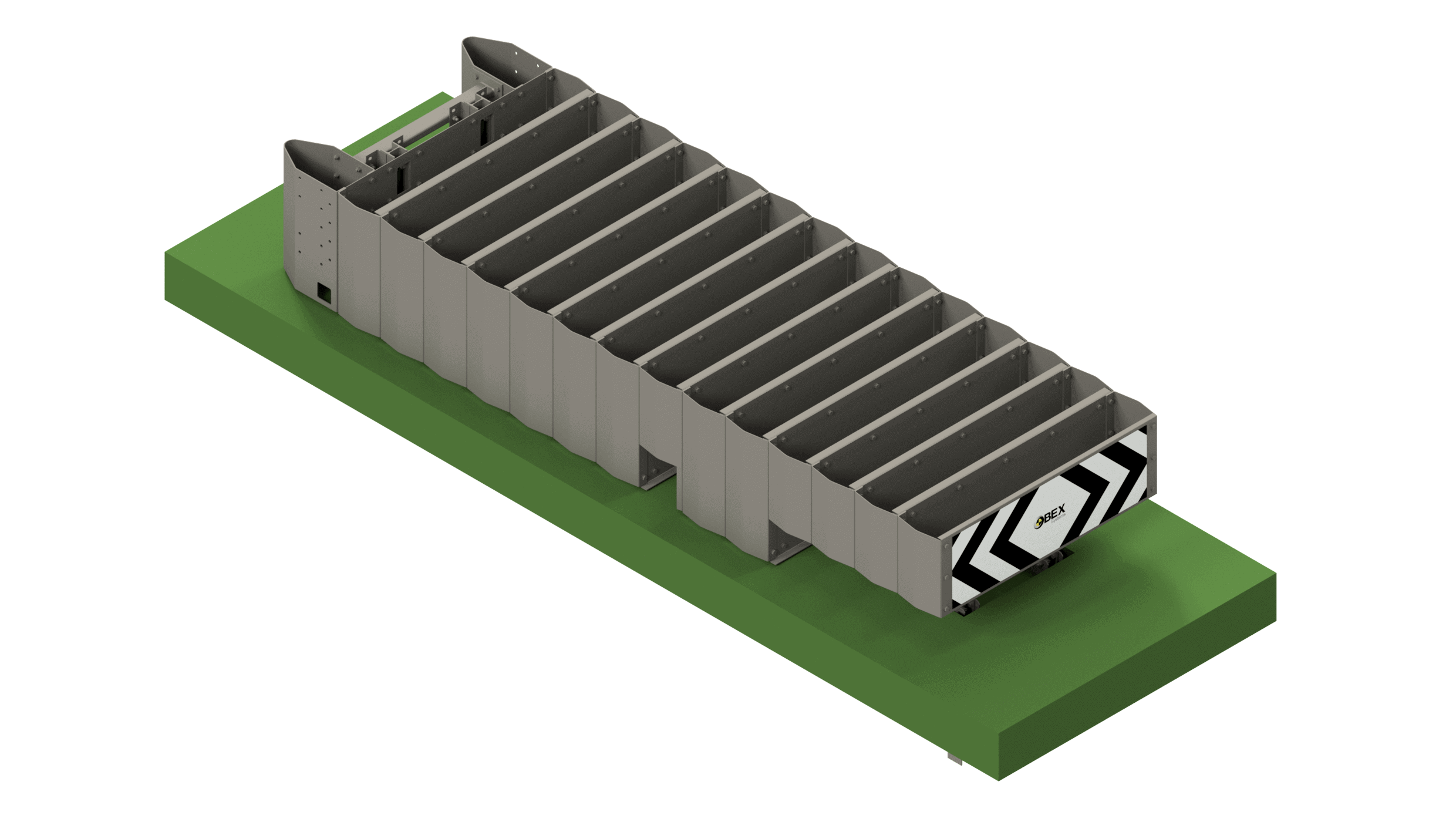

The META13 steel parapet has undergone full-scale crash tests, according to European Standard EN 1317-2, at the CIDAUT Road Infrastructure Safety Laboratory in the town of Mojados (Valladolid) Spain, and met all the acceptance criteria for High Containment level H2.

The device is approved according to Standard UNE EN 1317 Parts 1 and 2 that, together with compliance with Part 5 regarding production control, has obtained the CE marking.

The META13 steel parapet has been tested on a cantilevered slab to simulate the actual conditions of the bridge decks.

Following full-scale tests, the META13 steel parapet has been awarded the CE marking according to European Standard EN 1317-5.

We renew the CE marking of our META13 metal parapet every year through an audit by the certifying body AENOR, which ensures that the materials and the manufacturing processes are compliant with the declaration.

The parapet components are made of quality hot-rolled steel sheet S235JR, S275JR and S355JR, according to Standard EN 10025, and hot-dip galvanised according to Standard EN 1461. The finish of this product can be reinforced with combined anti-corrosion treatments: hot-dip galvanising + powder coating.

- Reliability of the containment system following testing in the worst possible scenario on a cantilevered bridge deck.

- The reduced dynamic deflection DN=0.6 m and the excellent working width WN=0.8 m (W2) of the system mean that it can be installed on supporting elements of optimised dimensions.

- These properties allow for the installation of acoustic screens and vandal-proof fences at very short distances from the parapet.

- System with shear anchor. In the event of a collision, it is rapid, simple and cheap to replace, with no structural alterations to the bridge deck.

- Simple assembly due to its small number of components.

- Can be transformed into an H3 system.

- System versatility, as it can act as both a vehicle and a pedestrian containment system by installing a grille.

- Alternative anchoring systems can be adapted for existing bridges.

- Hot-dip galvanising of all its components according to Standard EN 1461.

- Powder coating in the different standard colours of the RAL chart.

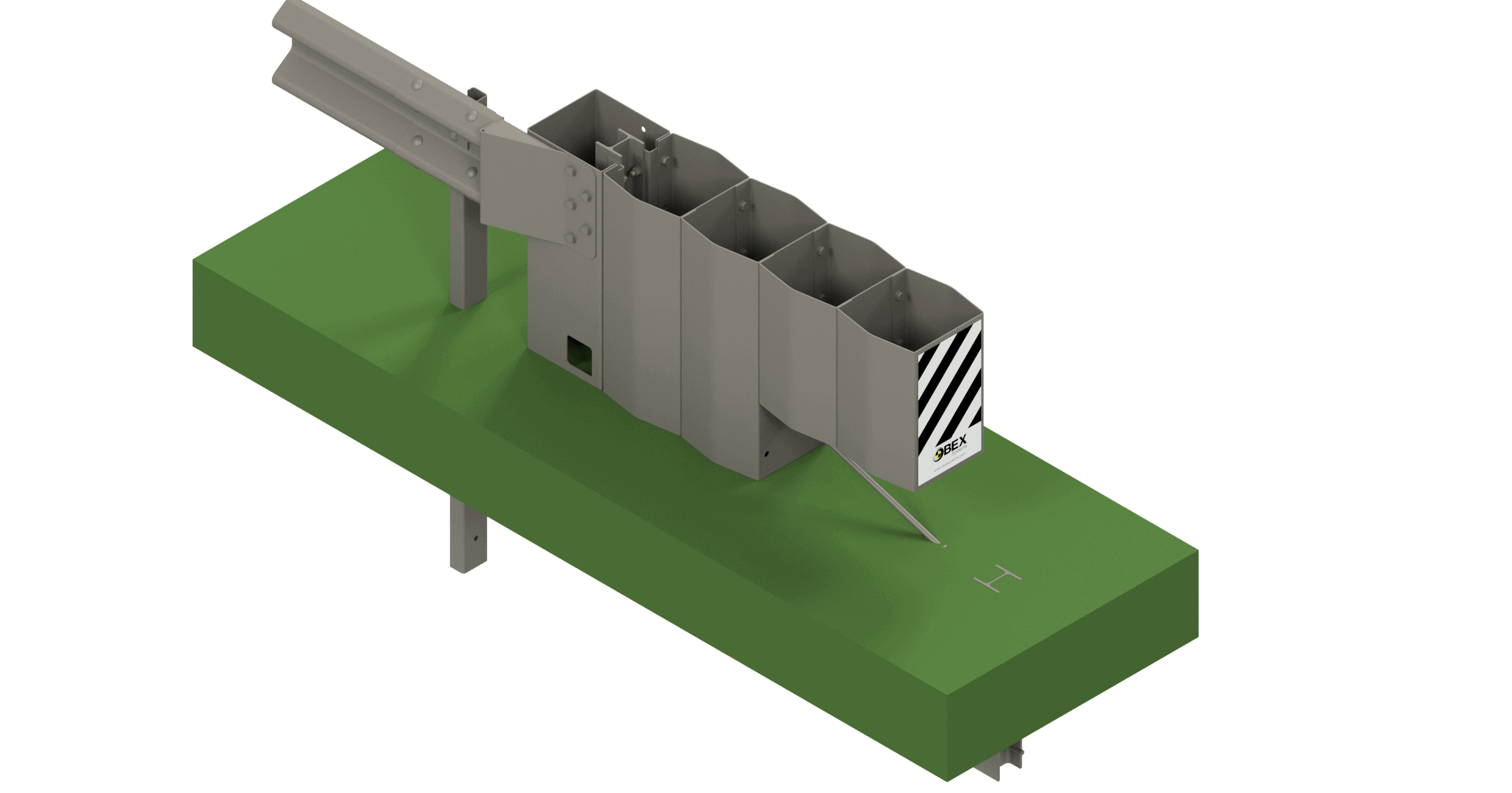

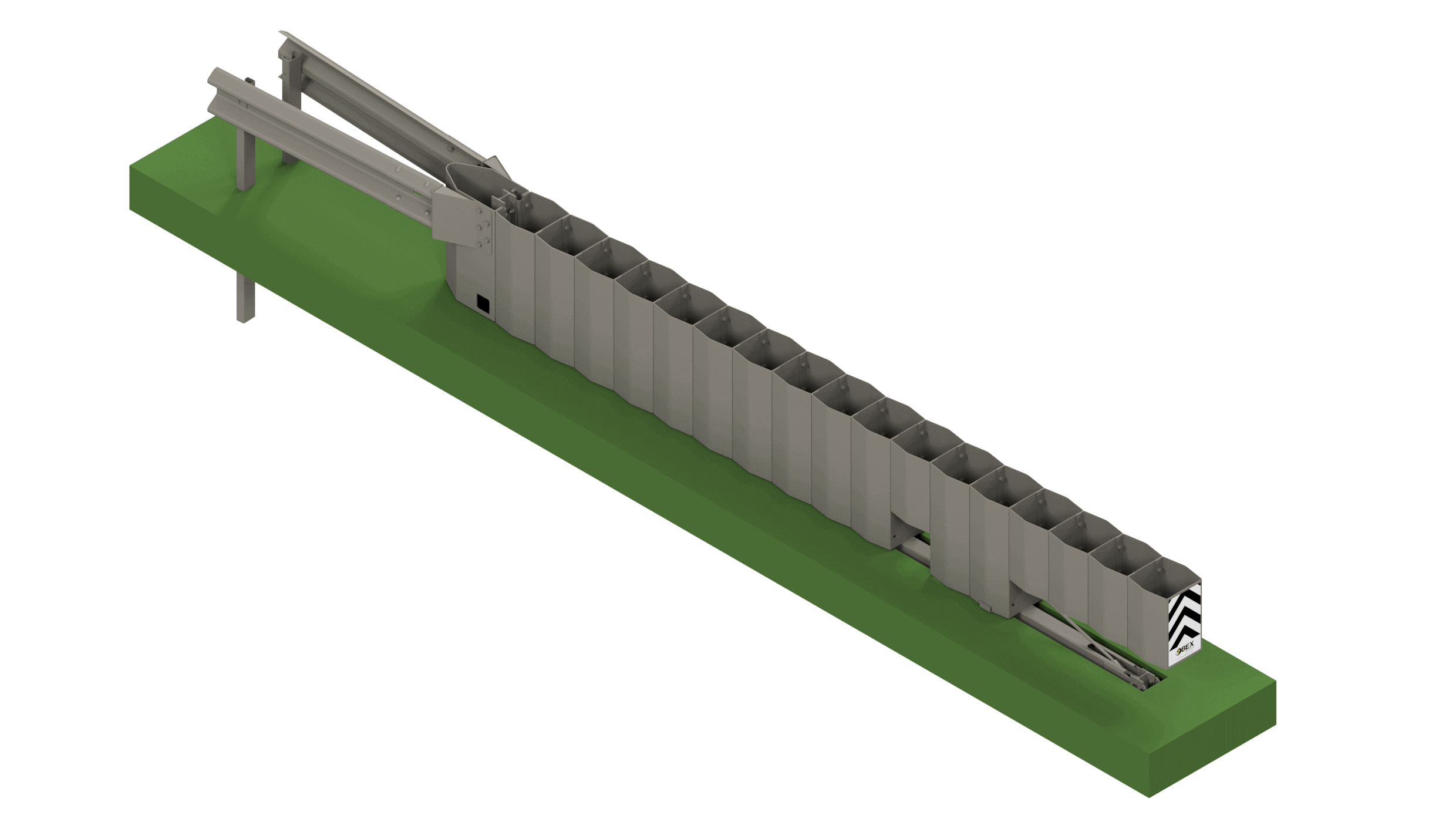

TRANSITIONS:

See the diagrams of the different transitions adapted to each device type.

TREATMENT OF EXPANSION JOINTS:

Installation of adapted expansion connectors to absorb the displacement expected by the expansion joints of the structure.

SYSTEM HEIGHT:

Height of upper bar = 1235 ± 25 mm.

ANCHORAGE:

The parapet can be installed with two types of anchorage:

- Standard anchorage

Anchoring system composed of a plate with threaded eyes embedded inside the concrete

- Chemical anchorage

Anchoring system composed of a plate bolted to the structure by chemical anchoring.

This anchorage system is designed to anchor the post of the META13 parapet / META16 to decks where the standard anchor plate cannot be embedded.

The parapet post is anchored to the anchor plate using the same bolts and shear anchors as those used in standard anchorage.

Equivalence between chemical anchorage and standard anchorage

The equivalence of chemical anchorage and standard anchorage in the event of vehicle impact is shown in the high-energy pendulum test performed at the Spanish Road Infrastructure Safety Laboratory (CIDAUT).

Both anchoring systems always produce breakage of shear pins on impact. The deck does not suffer any significant damage.

ANCHORING BEAM:

The reinforced concrete beam on the edge of the deck is joined to it for easier anchoring of the posts of the META13 parapet (see detailed diagrams and installation manual).

Aspects to consider for the proper functioning of the parapet:

The META13 parapet has been designed with a reduced edge beam that minimises the reinforcement volume and concrete to be used. The full-scale test was performed using the same lightweight beam, meeting European Standard EN 1317 when it requires the on-site use of the same slab that was used in full-scale testing to obtain the CE marking. Circular-Order 35/2014 sets out the conditions under which this slab can be modified, but also indicates that the amount of reinforcement per linear metre used in full-scale testing can never be reduced.

The deformation of the metal parapets is characterised by the working width “W” and dynamic deflection “D”. When choosing a vehicle containment system, the working width is one of the most important features to consider, as anything located behind at an incorrect distance would cause the system to malfunction.

GALVANISED: Hot dip galvanising anti-corrosion treatment according to EN 1461.

POWDER COATED: Protection using polyester powder coating, applying the QUALISTEELCOAT process based on Standard EN12944 according to the RAL colour requested.