Hot dip galvanizing is an anticorrosion protection commonly applied to steel. It provides excellent performance when it comes to resistance against the natural process of oxidation, and ensures long product durability.

Phases of hot dip galvanizing

Receiving and shipping

Acid degreasing

Pickling

Washing

Fluxing

Drying oven

Galvanizing

Air cooling

Optional passivation

Checking and shipping

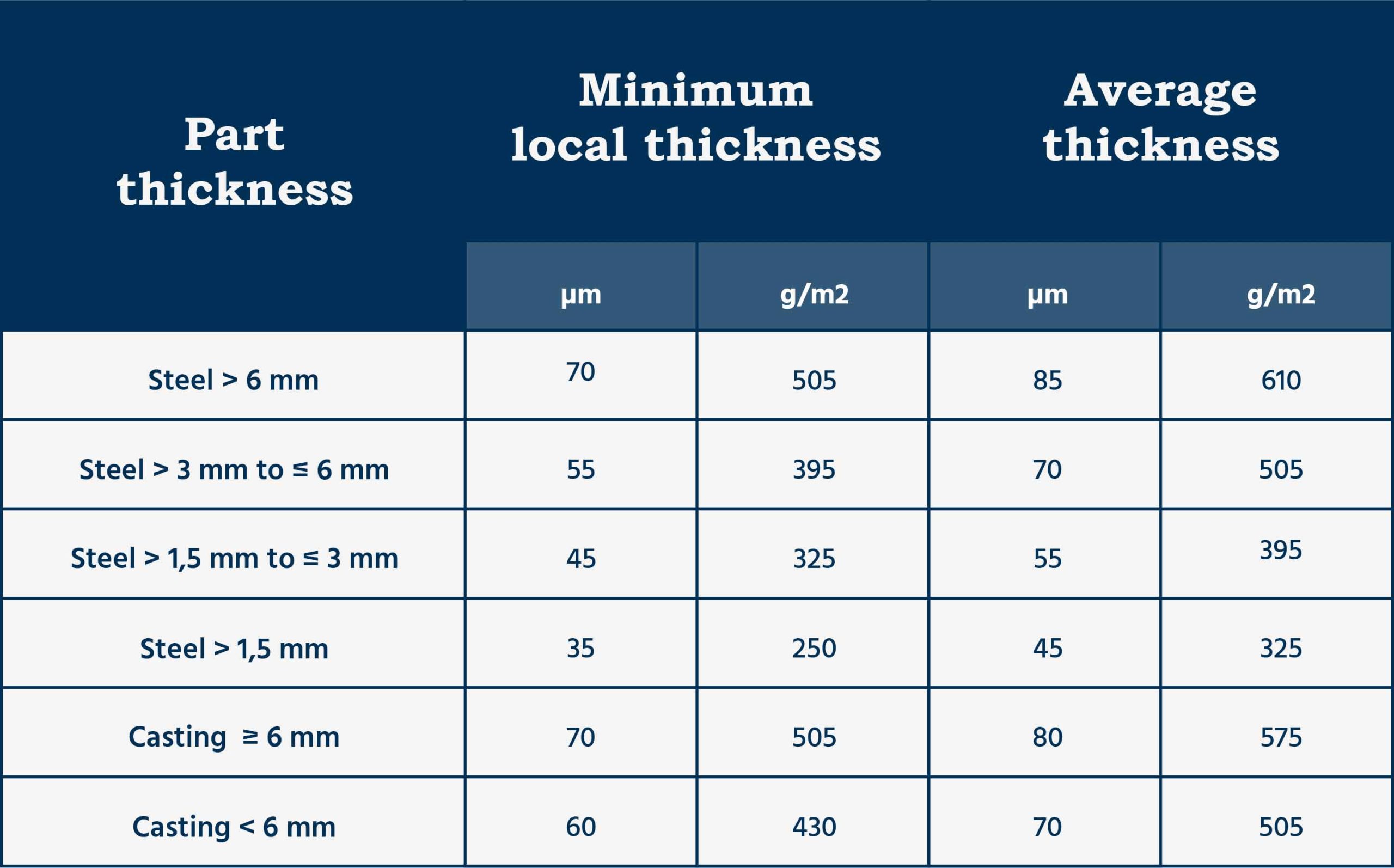

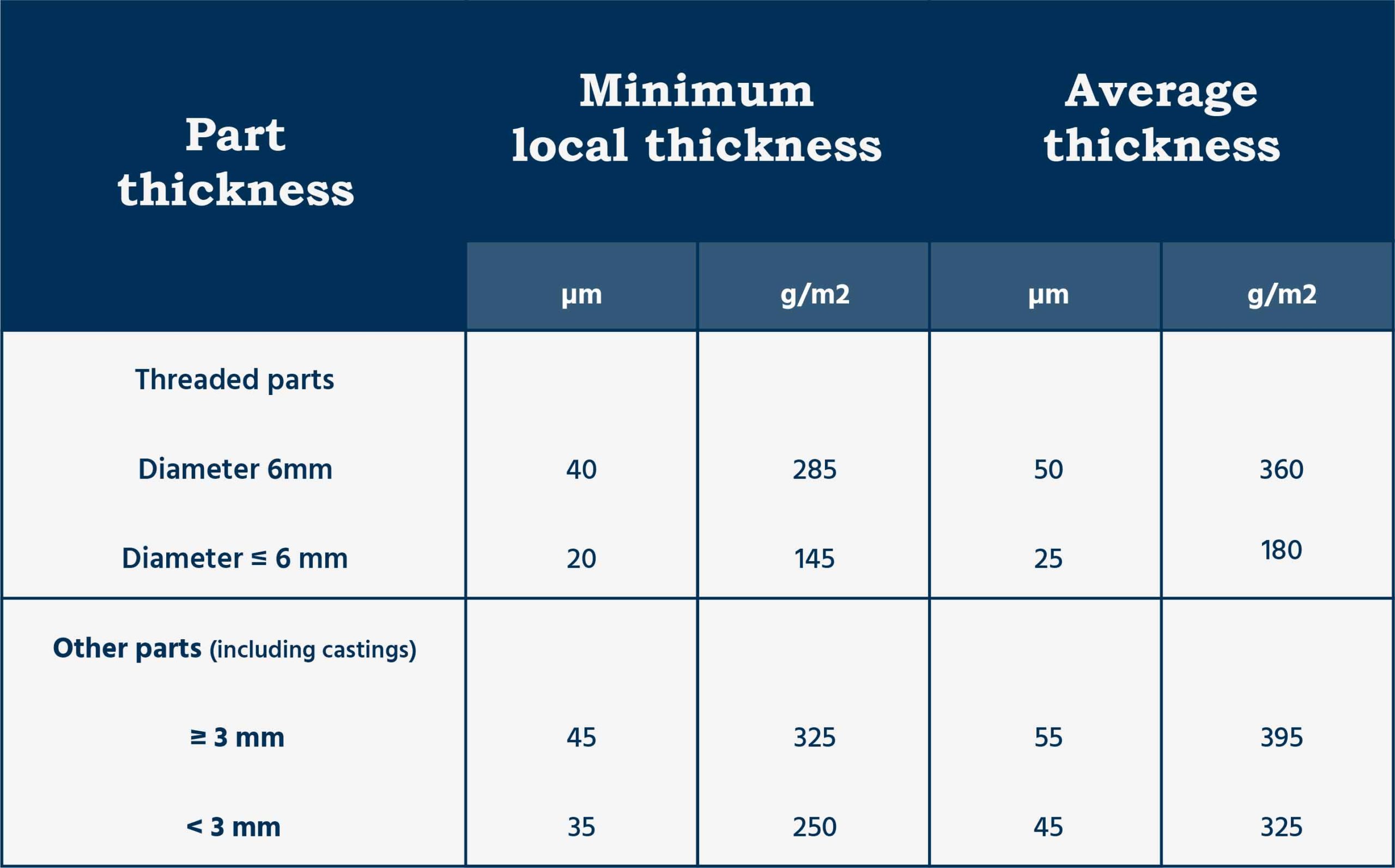

Coating thicknesses

The reference standard for this hot dip galvanizing process is UNE-EN ISO 1461. According to this, galvanized pieces should be at least the following zinc thicknesses:

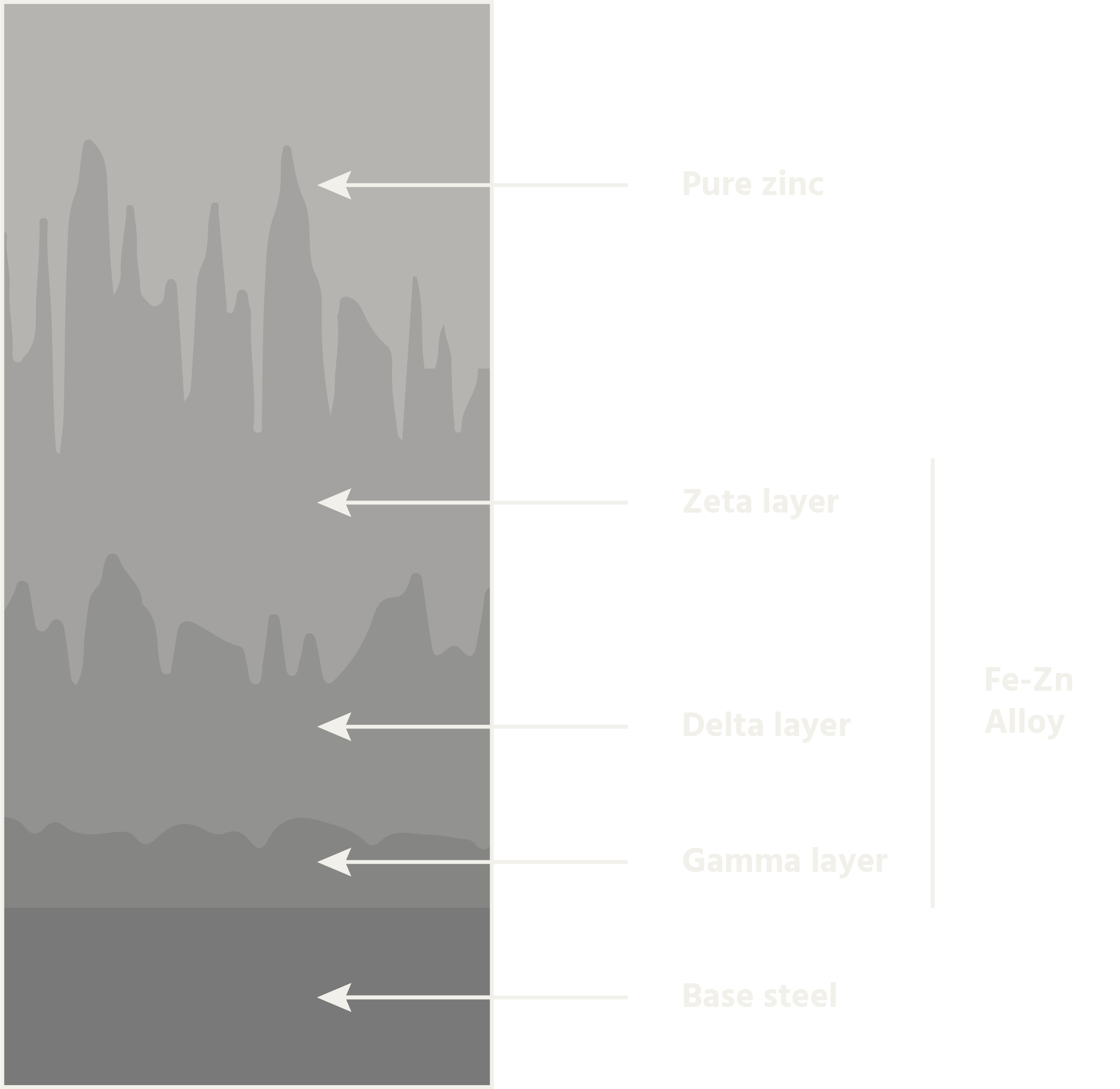

Forming of allow layers

During the hot dip galvanizing process, three alloy layers are formed into the intermetallic relation Fe-Zn, in addition to an exterior pure zinc layer, which all together provide the equipment with excellent properties of corrosion resistance.

With this coating, the so-called “galvanic cell” is formed, which protects galvanized pieces against any local damage where steel base may be exposed. It is a located cathodic protection in which the zinc acts as an anode of sacrifice.

Visual finishing

Different color appearance

The visual finishing oh hot dip galvanized elements may vary from one piece to another, even between different areas of the same piece. Common visual characteristics of just galvanized steel pieces include high glittering, crystals, dull gray matte and / or a combination of those. This may not be consider as defects under any cricumstance.

REASONS:

1. Different chemical composition and different reactivity of the steel

2. Different cooling speed

- All finishings prove same resistance against corrosion.

- Aging will make this appearance differences less noticeable.

Zinc accumulations

Always accepted while not interfering with the use given to the piece, or unless specific customer requirement.

Distortion

It may be caused because steel must adapt itslef to thermal expansion when very different steel thicknesses or asymmetrical parts are mixed steel.

Zinc splatter

Splattering and low adherence zinc flakes may be formed when humidity on the surface of the galvanizing bath cause splashes on the product. Such flakes can be easily removed by gentle brushing.

Such removal does not affect the corrosion resistance and it's not cause for rejection.

White spots

White spots due to humidity during storage period are formed by zinc oxidation. This is not cause of rejection, while coating thickness remains above the specified minimum value.

The hot dip galvanizing process can cause some or all previously mentioned issues. None of those effects may be considered neither defects nor reason of rejection. They are quite common and accepted by the norm of this process.

Would you be interested to see our products?

We advise you without obligation