Vehicle containment systems regulations

- For more detailed information about this standard, access the section dedicated exclusively to the European Standard UNE EN 1317, where we summarize the clauses that apply to metal parapets.

- If you still have doubts, you can also review our frequently asked questions page or directly contact our R&D team.

We use various Eurocodes based on the nature of the project, the elements involved in it or the environment for which it is intended. For example, Eurocode 2 for structural concrete projects and Eurocode 3 for structural steel projects.

Frequently asked questions

As we can read in the subsection 6.1.1. Generalities of section 6.1. Longitudinal arrangement of Circular Order 35/2014 on application criteria for vehicle containment systems of the Ministry of Public Works, safety barriers and parapets require a minimum installation length to be able to function properly against the impact of a vehicle. When the vehicle containment system is installed in isolation, without being linked by transitions to another system, then the minimum length will be in accordance with the arrangement used in the crash tests in which the CE marking has been obtained, according to the standard UNE EN 1317. On the other hand, when a vehicle containment system is used that is linked by transitions to another system, in such a way that continuity is maintained, as it is not necessary for the system to function in isolation, the minimum lengths indicated above may be reduced. Given that, to date, a European regulation has never come into force that regulates the CE marking of the transitions between adjoining containment systems, these will be installed in a similar way to how they were arranged in the test with which the CE marking of the system was obtained. containment itself.

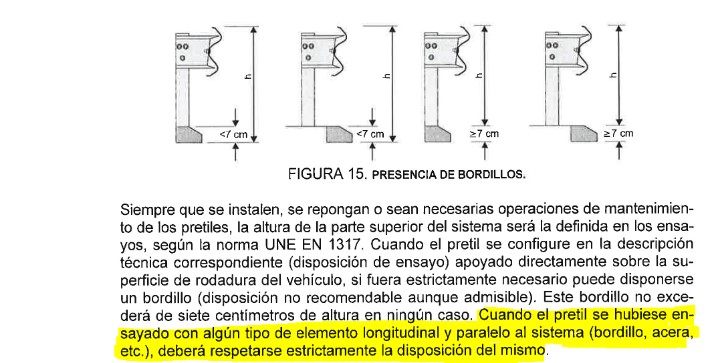

Yes. This issue is clarified in section 6.3 Arrangement in heights of Circular Order 35/2014 on Criteria for Applying Vehicle Containment Systems, more specifically in the final paragraph:

From this text it follows that, if it has been tested with a kerb, the arrangement of it must be respected. In our case, 12cm. On the other hand, it is clear that, if the VCS has been tested without a kerb, a kerb of up to 7cm in height may be available, although it is not recommended.

The correct thing is to choose the containment system to be installed well in advance so that the deck takes its parameters and foundations into account. In case of discrepancies, Circular Order 35/2014 establishes and limits the manner in which modifications can be made to the slab with respect to the one tested.

“The definition of the slab in the tests of each parapet with which the CE marking has been obtained represents the minimum value of it in whatever reinforcement, concrete strength and geometry refers. When the punching load values have been obtained during the tests, other geometries and reinforcements for the slab may be calculated, without reducing the amount of reinforcement in any event.”

Excessive noise in cities and highways is a threat to human health. High levels of noise cause sleep disturbance, irritability, aggressiveness, respiratory problems, etc. Acoustic screens are the best corrective measure to minimize the propagation of noise generated by traffic on traffic routes by acting as a barrier between the receiver and the source of the noise. They are, therefore, the most widely used anti-noise systems in transport infrastructures due to their efficiency, their rapid installation and their value for money.

The severity of impact index classifies the risk to occupants of the vehicle into three levels of severity, A, B and C, with A being the least serious. The installation of high containment level systems with a severity index of C is currently prohibited in Spain.

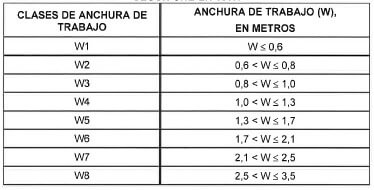

The working width is typified with a special coding from W1 to W8, with W1 being the one with the smallest displacement. The systems usually marketed in Spain are in the range W2 to W5.

When the steel parapet is intended to protect a vehicle from impact with an obstacle, for example, large signage, acoustic screens, pedestrian crossing areas, etc., the working width class will be selected based on the table previous. If there is no obstacle behind the barrier that the vehicle can hit, the working width is not a relevant parameter to take into account.

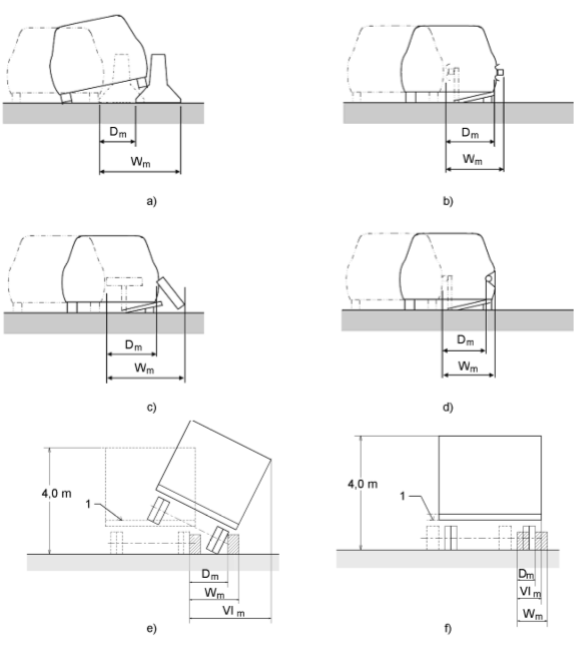

Dynamic deflection is the maximum lateral dynamic displacement on the side of the VCS facing the traffic. Working width is the distance between the side of the containment system closest to the flow of traffic before the impact and the furthest lateral position that reaches any essential part of the system. The Standard classifies this parameter from W1 to W8 depending on the meters of displacement. This is the maximum dynamic lateral displacement of the side of the barrier facing traffic without deforming. It is evaluated using photographs or high-speed video and considers a hypothetical load with width and length equal to that of the floor of the vehicle, and a total height of 4m. The Standard classifies this parameter from VI1 to VI5 depending on the meters of displacement. Standard UNE EN 1317 includes the following illustrations to better understand each term.

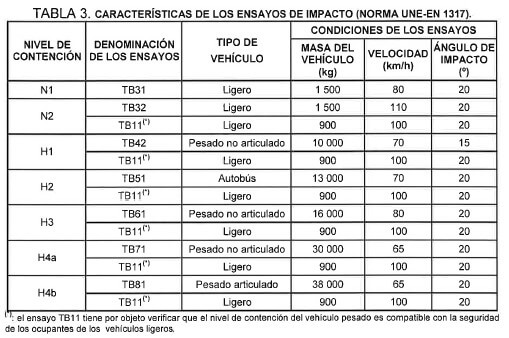

Section 3.2 of Circular Order 35/2014 refers to UNE-EN 1317 when it explains that vehicle containment systems must pass a set of tests under specific execution conditions.

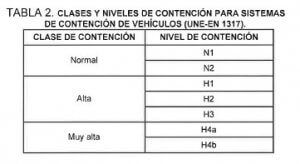

Section 3.2 of Circular Order 35/2014 refers to UNE-EN 1317 when it explains that vehicle containment systems must of the options shown in the following table: