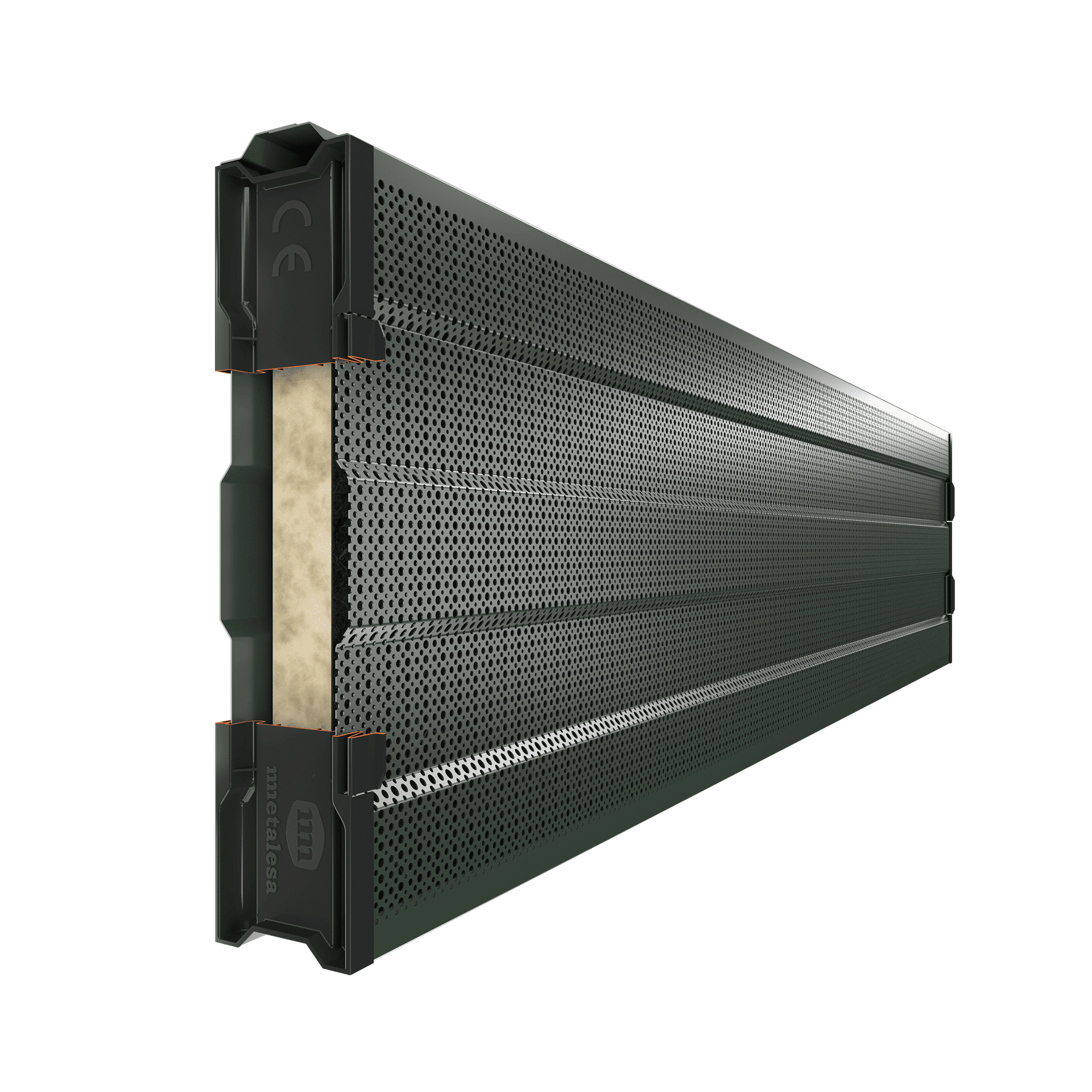

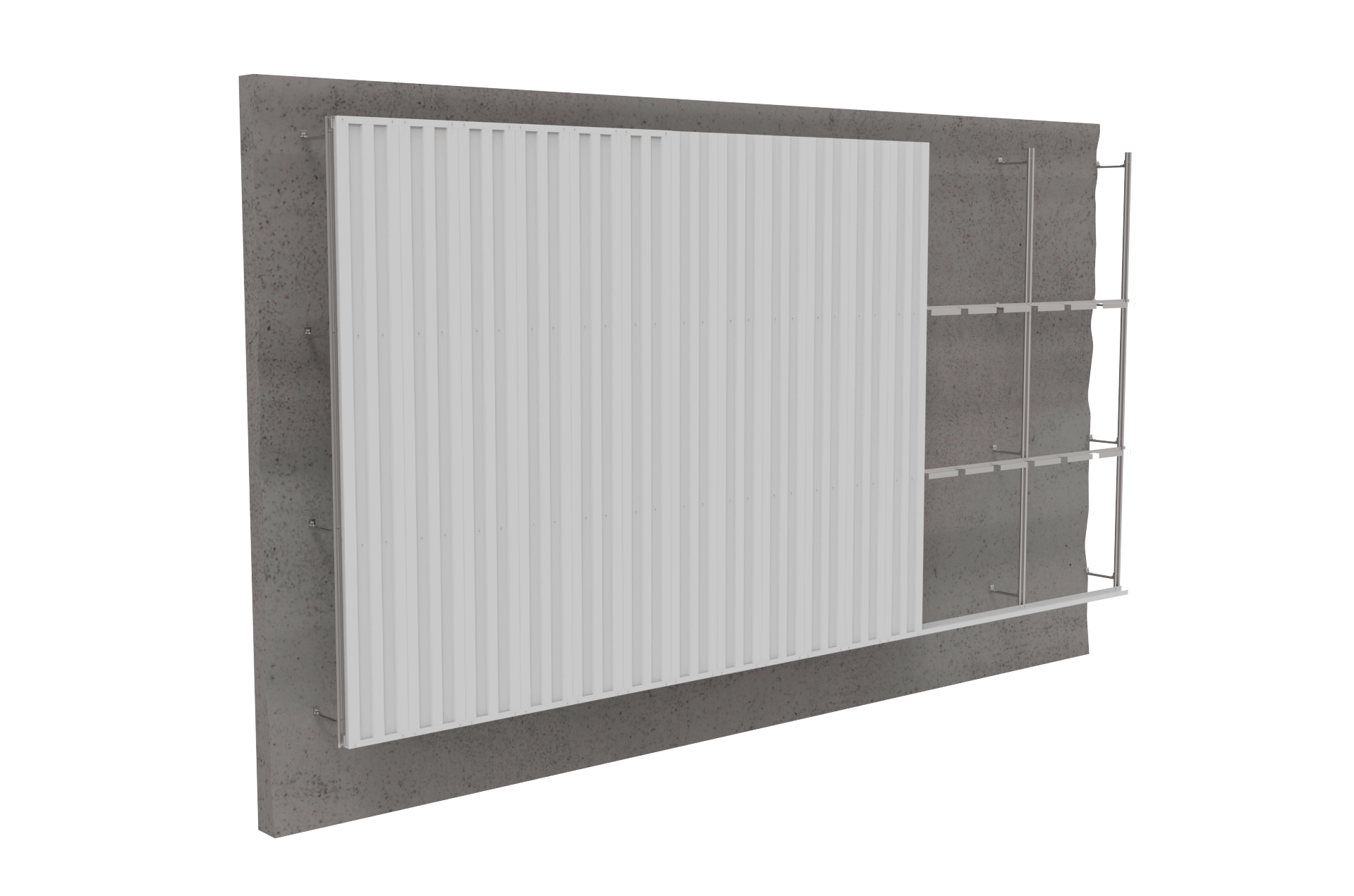

Steel acoustic panel MG3

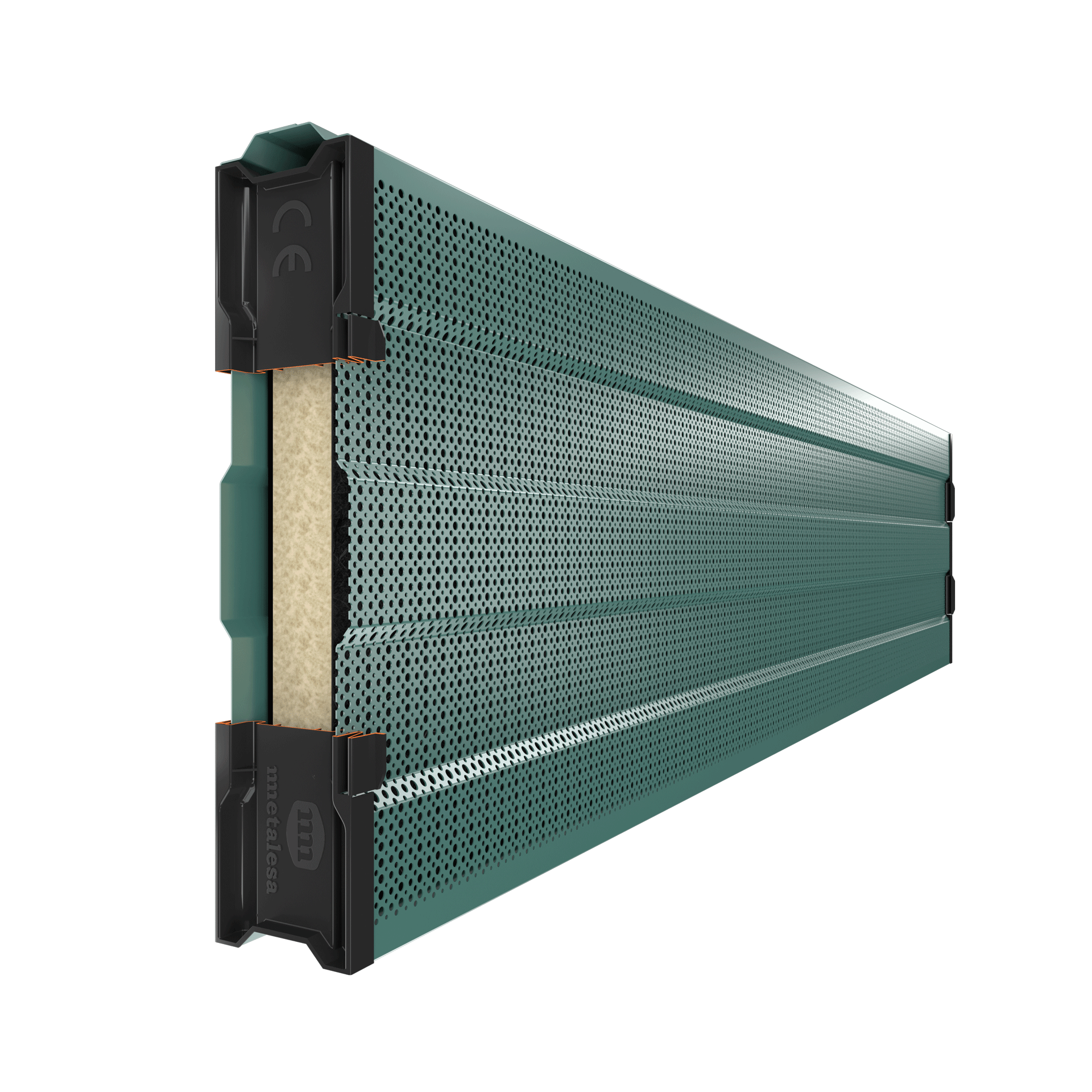

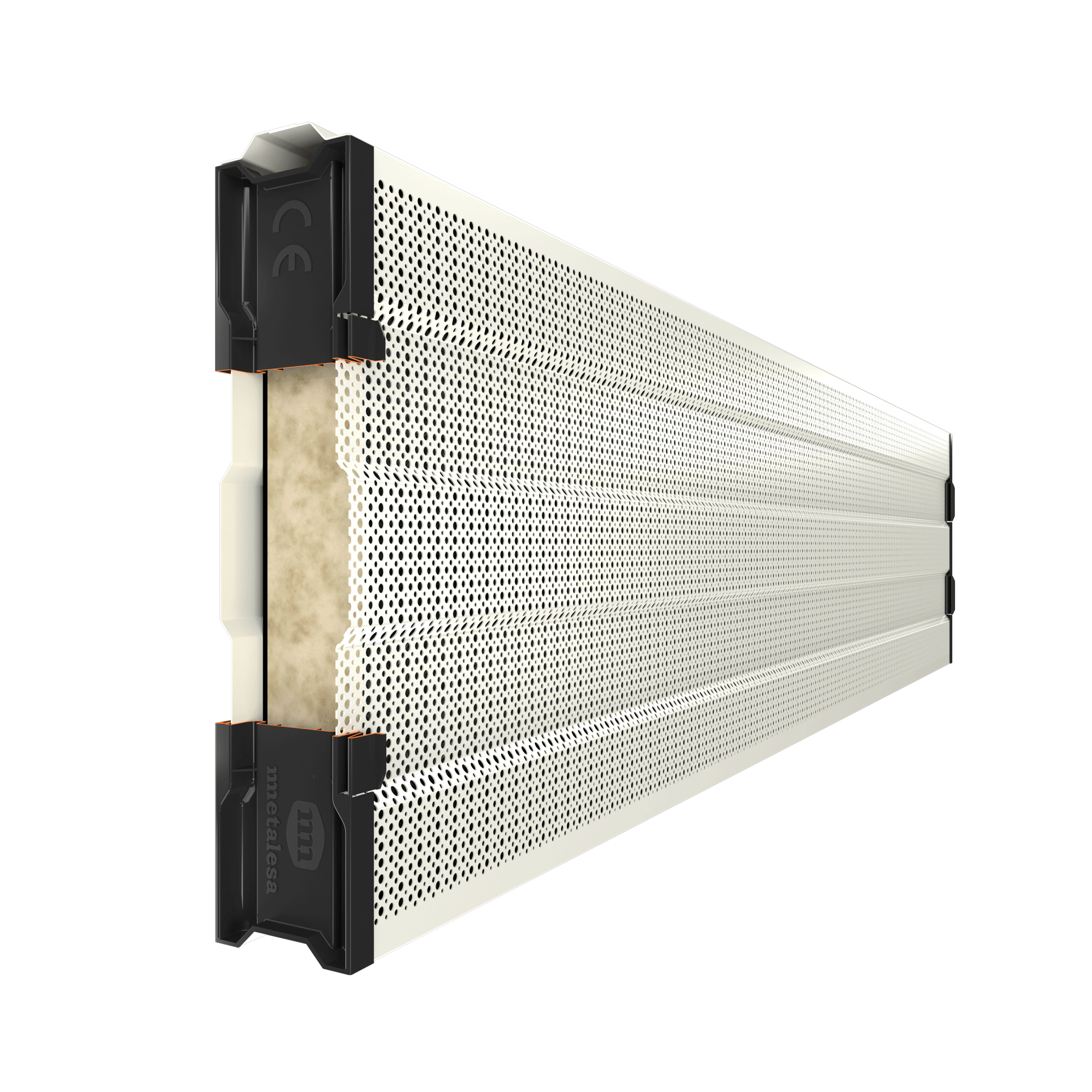

The MG3 sound-absorbing panel consists of two profiled and powder coated steel sheets, one with perforations (absorbent side) and the other smooth (reflective side). When joined, they form a housing that is closed at the ends with a polypropylene cap. Rock wool with black protective facing is placed on the inside and between both sheets of steel.

The panel fits up to profiles type HEA/B 180.

| Reference: | |

|---|---|

| Weight: | |

| Documentation: | |

| Availability: |

Technical Information

Acoustic Parameters

- Absorption Class: A5

- Insulation Class: B3

- Absorption Rate (DLa): 20

- Airborne Sound Insulation Index (DLᵣ): 26

- Weighted Sound Reduction Index: 33 (-2;-7)

- Front/rear plate combination: PERFORATED/BLIND

Geometric Characteristics

- Panel thickness (mm): 110

- Front plate thickness (mm): 1

- Rear plate thickness (mm): 1

Mechanical properties

- Design Load (Kg/m²): 223.3

- Panel length (mm): 4000

- Panel Height (mm): 500

Panel Morphology

- Material: STEEL

- Is it absorbent for both sides?:

- Assembly: SELF-TAPPING

Components

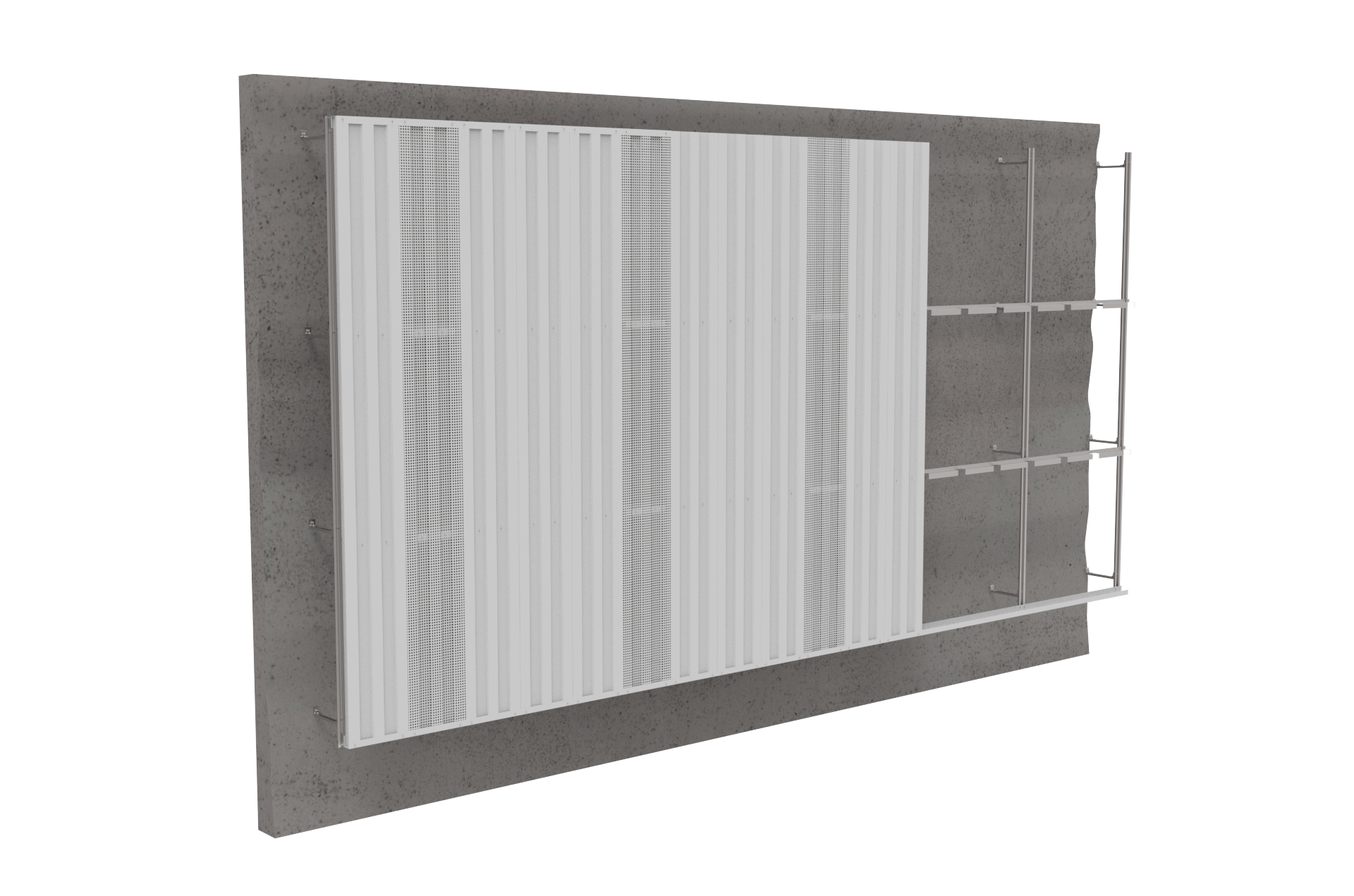

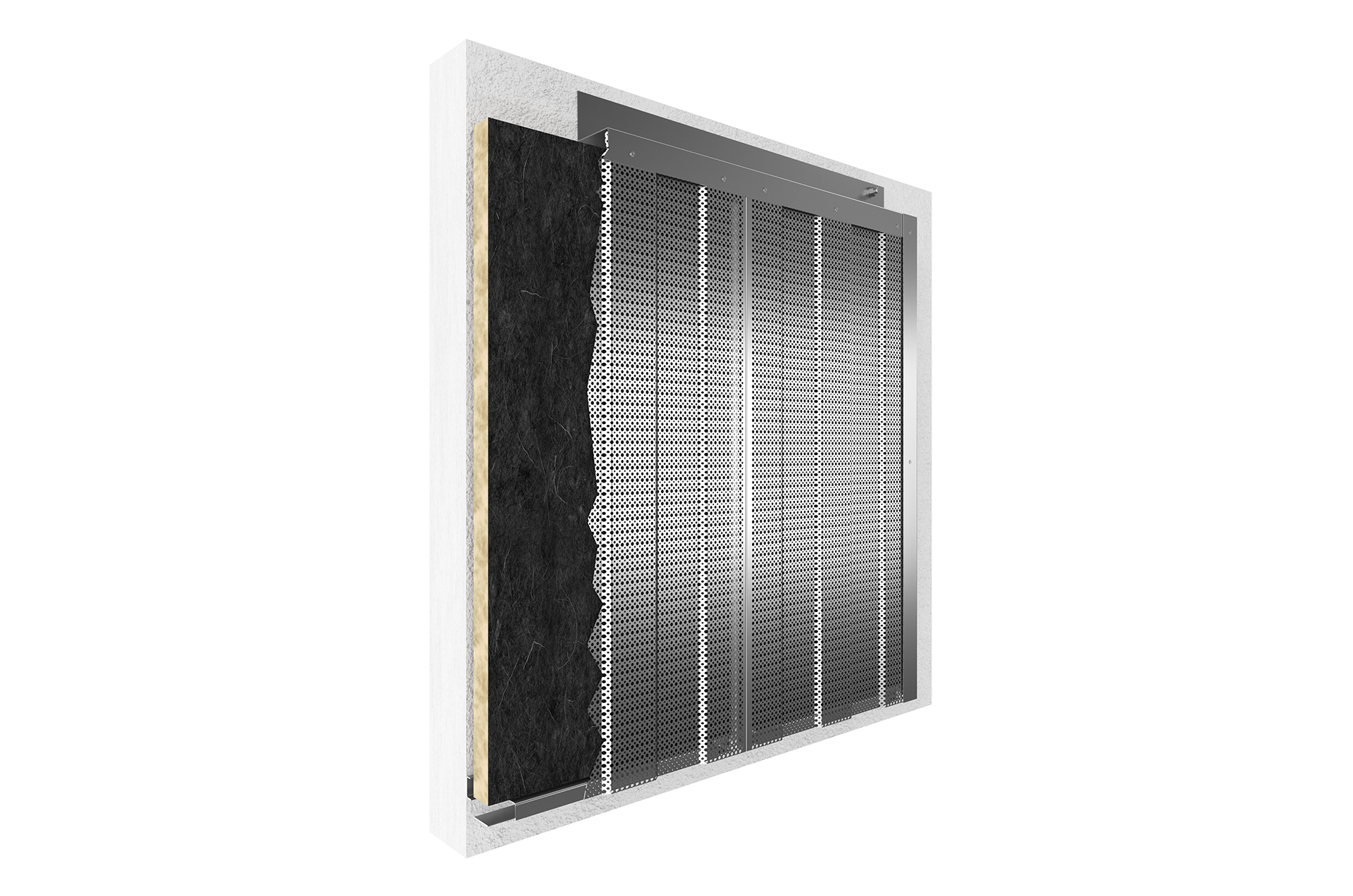

- Absorbent side facing the source of the noise: The absorbent side is a multi-perforated metal element. The design of the perforations means that the sound wave penetrates the panel and is dissipated in the absorbent material.

- Sound-insulating: Rock wool reduces the sound level thanks to its fibrous, elastic nature, which dissipates the energy of the penetrating sound waves.

- Reflective side: There is a space between the reflective side and the rock wool that creates an acoustic chamber so that the sound waves reflect on it towards the absorbent material.

- Side closures: Polypropylene caps. These are adapted to the inside of the posts to ensure sound impermeability and panel immobility.

Benefits

- Panel configuration provides maximum insulation and absorption.

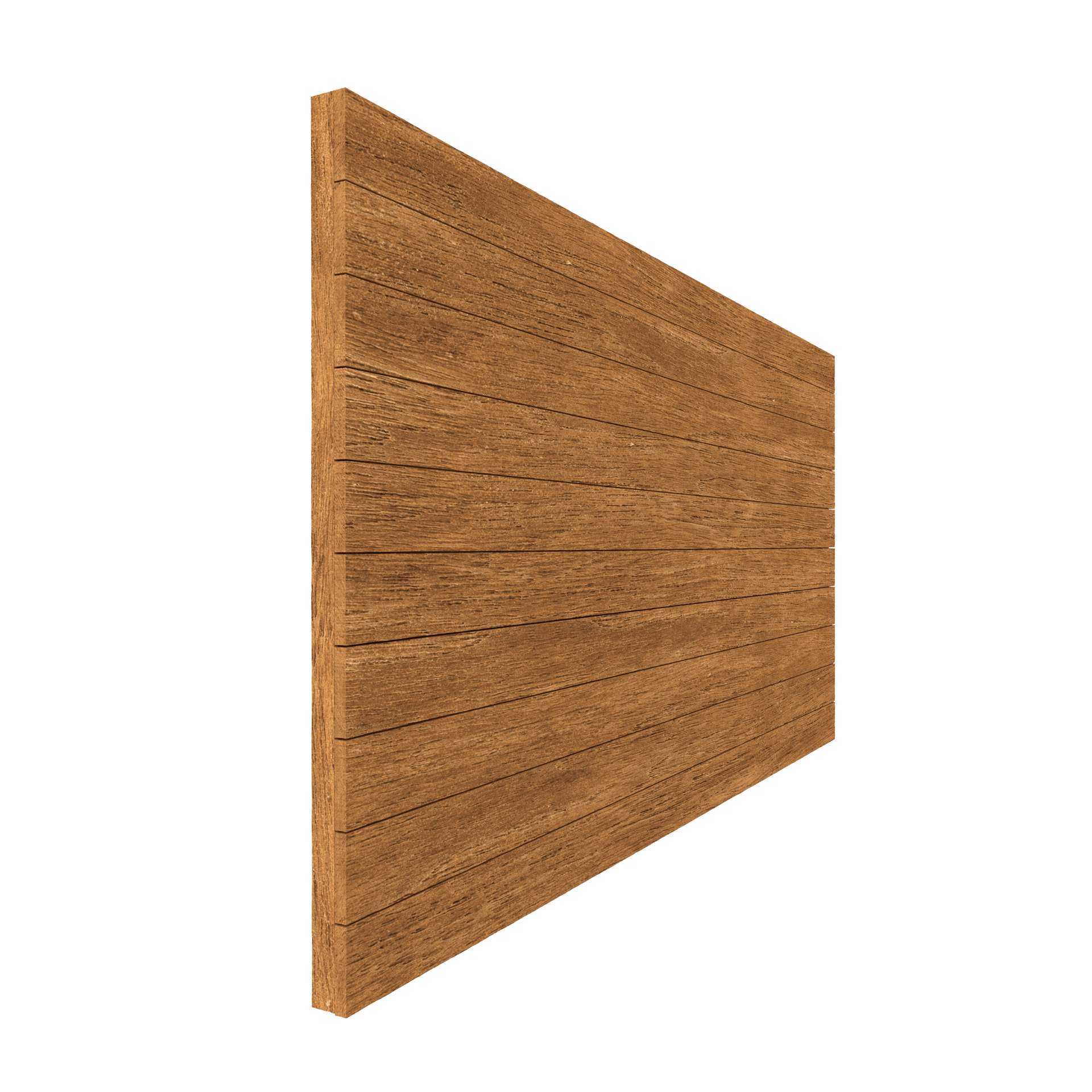

- Its appearance means it blends in perfectly with the landscape.

- Its varied designs result to different combinations.

- Thanks to its modular structure and lightness, the panel is easy to install.

- Long-lasting thanks to the quality of its components.

- Panel for road and rail infrastructure applications.

- High performance, resistant to wind loads and overpressure caused by rail traffic.

- Powder coating in the different standard colours of the RAL chart.

Acoustic and mechanical features

The acoustic screens manufactured by METALESA meet the requirements established for CE MARKING in compliance with EN 14388. The product is assessed by accredited testing laboratories:

- According to Standard EN 1793-1, sound absorption index DLα is obtained.

- According to Standard EN 1793-2, sound insulation index DLR is obtained.

- According to Standard EN 717-1, the weighted sound reduction index Rw (C;Ctr) is obtained.

The panels are mechanically tested according to EN 1794-1, having obtained very high loads in tests carried out in accredited laboratories.

For certain solutions, it is possible to guarantee mechanical properties through appropriate analytical calculations, as provided for in current regulations.

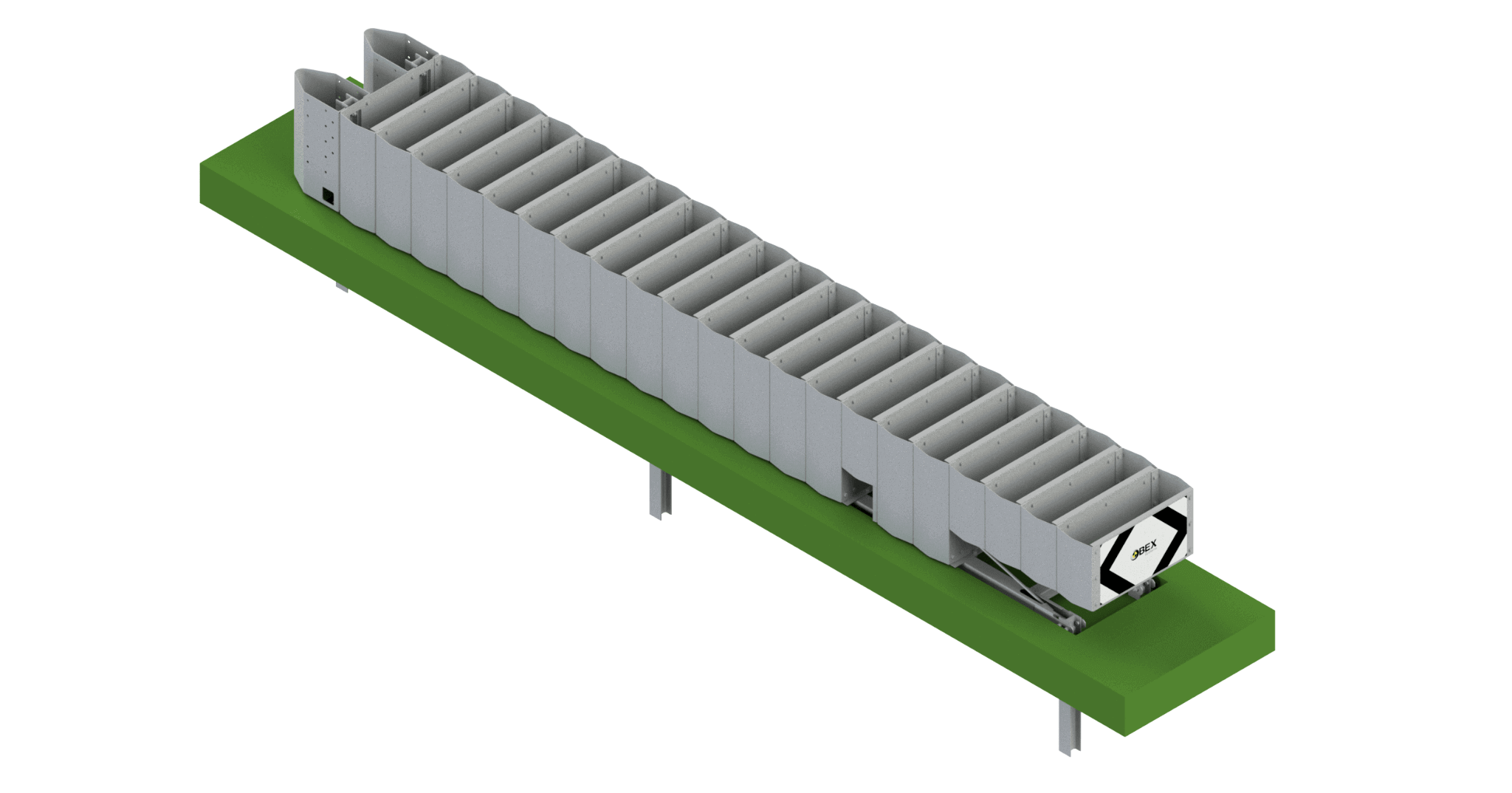

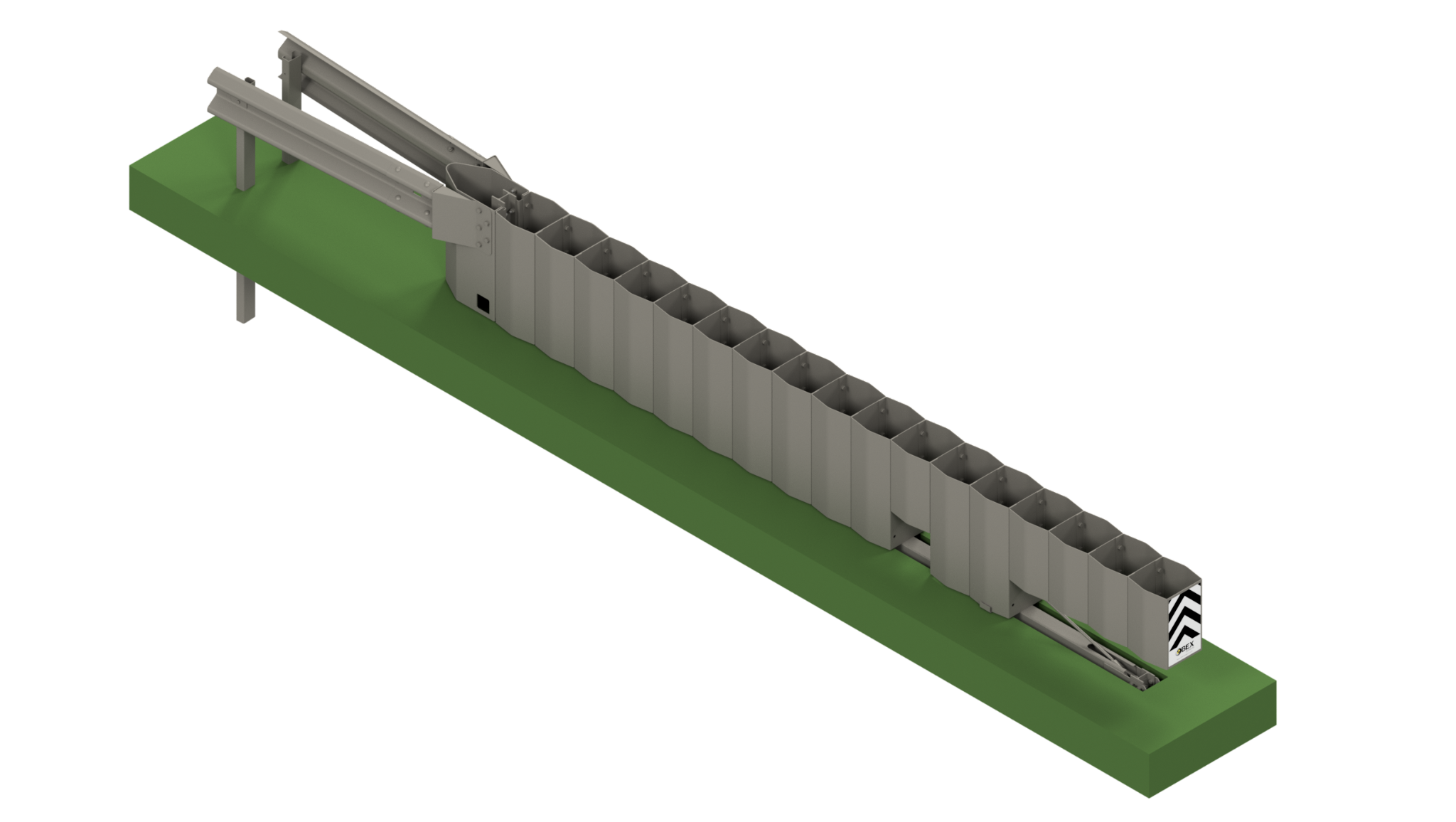

Installation

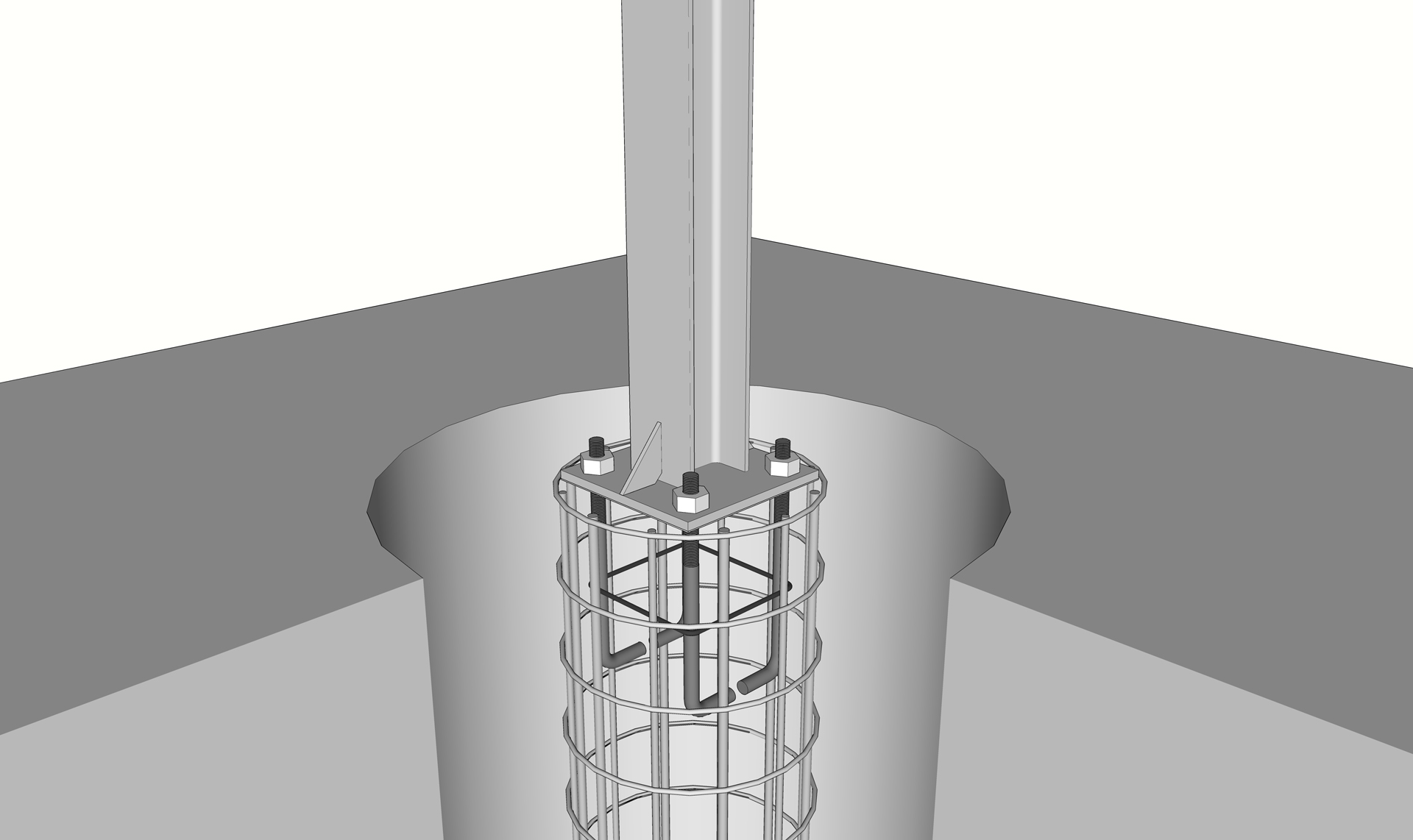

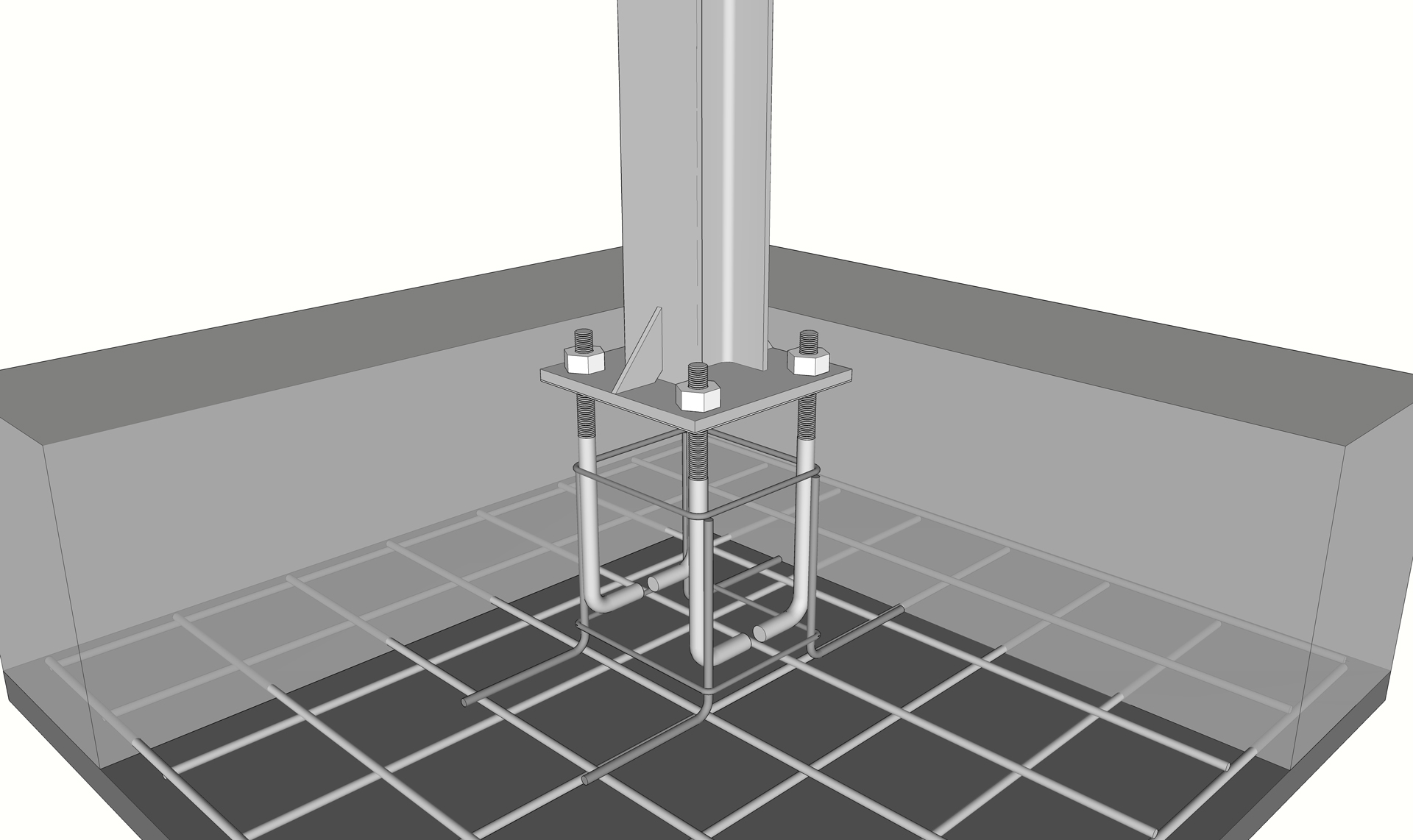

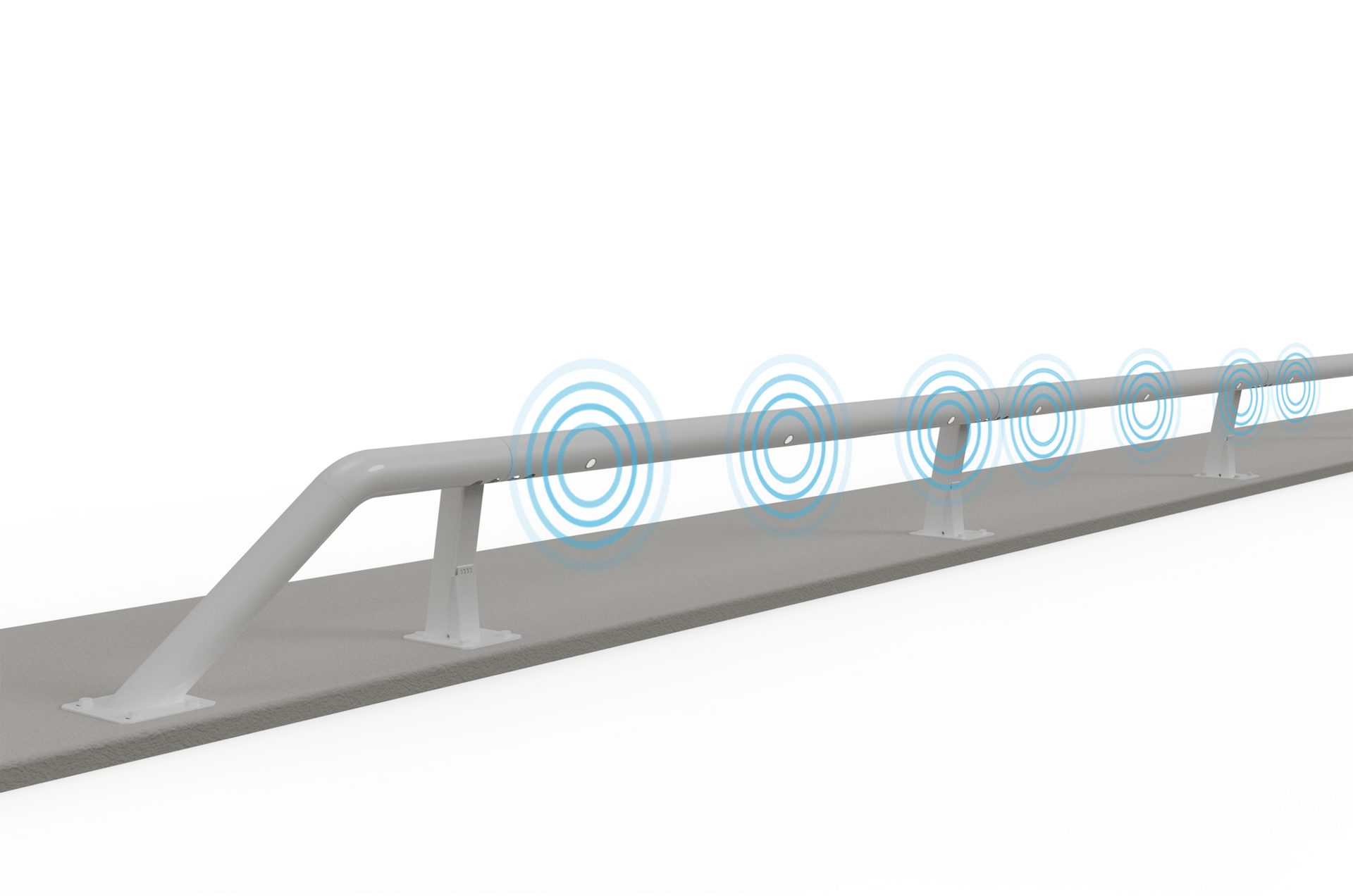

ANCHORAGES

The profiles are anchored to the foundations using bolts of a variable diameter and length, in accordance with the specific requirements of each project.

FOUNDATI ONS

The foundations provides the screen with structural stability, formed by pillars and acoustic panels, and must also guarantee the stability of the surrounding soil.

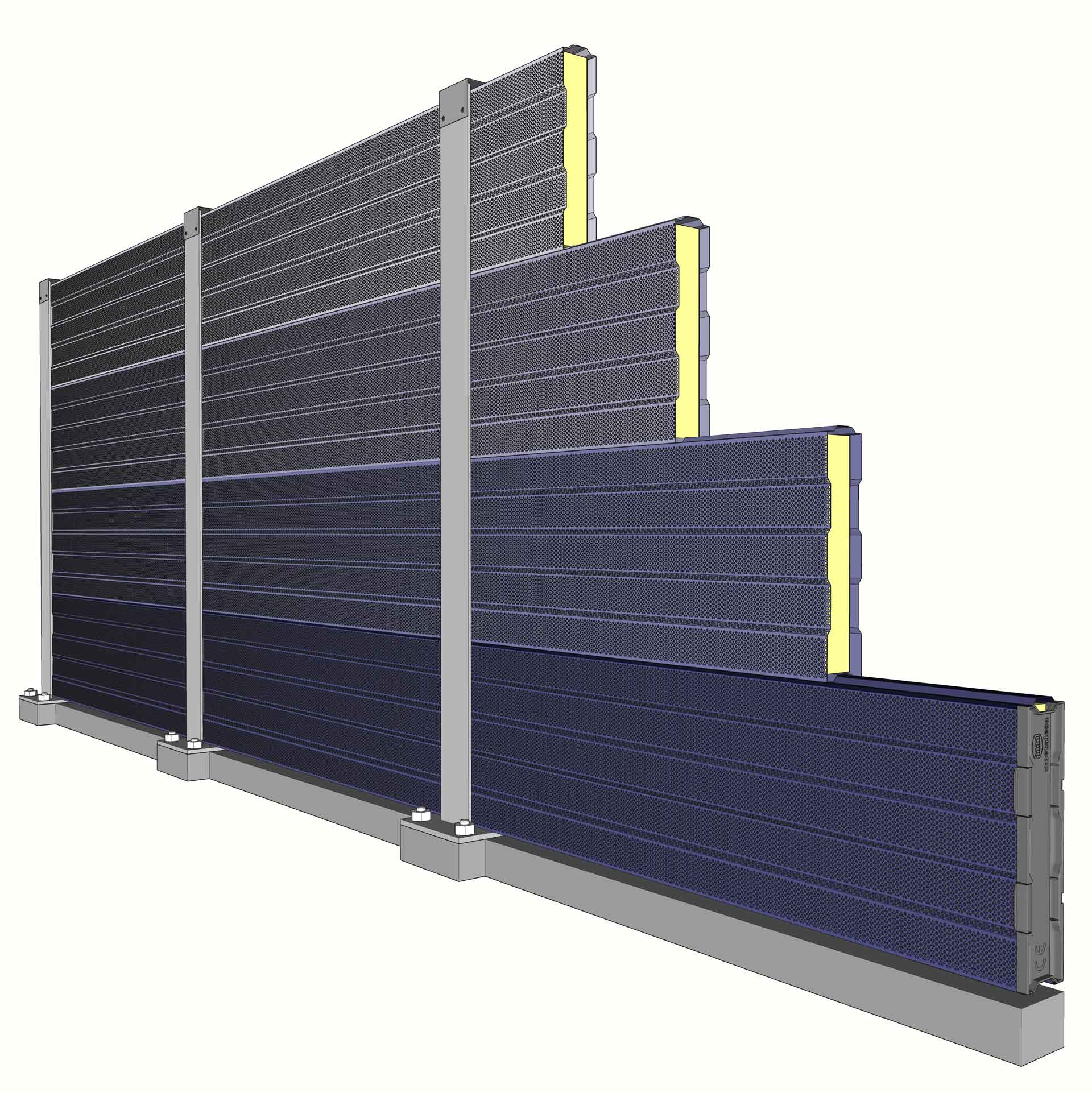

The panels are supported by HEB or HEA-type steel posts, anchored to foundations that must be calculated based on the study of the terrain, the wind resistance, etc.

PROJECT CALCULA TION AND OPTIMISATION

All aspects affecting the final efficiency of the screen must be considered: compliance with the on-site construction conditions, installation of the metal acoustic panel, type of panel, distance between posts, etc.

As important as the characteristics of the panels are: suitability of the type, height, insulation parameters, acoustic simulation, etc. It is also necessary to complete an appropriate foundation project to guarantee the stability of the system. Our engineering department plays a critical role in subsequent processes.

At the customer’s request, we complete all stages of the assembly process:

– Calculations of the foundations and supporting structure.

– Layout based on the topographic elevation.

– Building of foundations.

– Assembly of support profiles and installation of panels.

Our team of engineers has extensive experience in calculation and optimisation, and our team of fitters and associated subcontractors have been assembling acoustic screen solutions under all conditions for years.