Enhancing Seaside Promenade Safety with Advanced Infrastructure Solutions

With the arrival of summer, beach areas fill with tourists and residents eager to enjoy the sun and sea. Seaside promenades become activity hubs, hosting cyclists, pedestrians, and users of personal mobility vehicles (PMVs). However, the increase in users during this season highlights the urgent need to modernize and update road infrastructure.

In many seaside promenades, the separation between the road and pedestrian areas is insufficient, creating hazardous situations that could be avoided with proper planning and the delineation of these dangerous zones.

Today, the presence of cyclists, pedestrians, electric scooters, and other PMVs has grown exponentially.

These vulnerable users share spaces with motor vehicles, increasing the risk of traffic accidents. In many places, the road and seaside promenades are at the same level and lack effective barriers to contain vehicles in the event of a road departure accident.

This lack of separation can lead to dangerous situations, such as a vehicle leaving the road and invading the pedestrian area, potentially causing injuries or even fatalities. The absence of steel parapets or other suitable physical barriers significantly increases the risk of accidents in these crowded areas.

An effective solution to improve safety on seaside promenades is the installation of certified Steel parapets that ensure the safety of both drivers and vulnerable users.

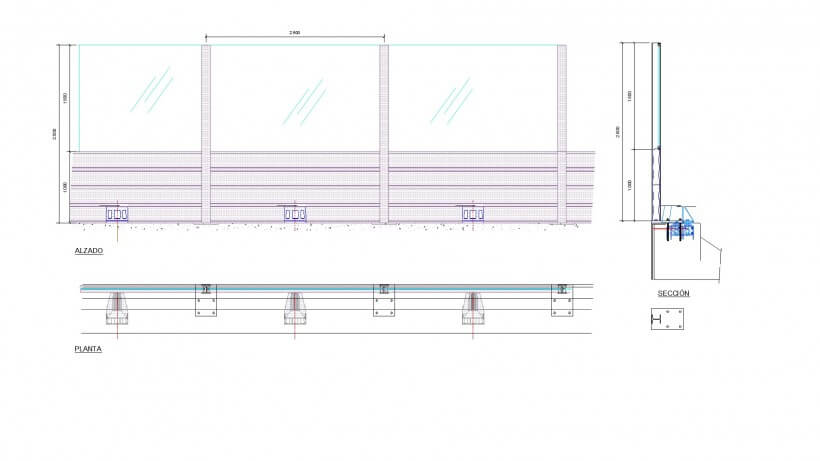

Our Metaurban steel parapet, with an N1-H1 containment level and CE marking, provides protection in these busy areas. The Metaurban® steel parapet is a vehicle containment system specifically designed for installation on urban or peri-urban roads, making it ideal for these types of roads. It is a certified device according to European standard EN 1317 parts 1 and 2, and with compliance with part 5 regarding production control, it has obtained CE marking.

The Metaurban steel parapet provides robust physical separation between the road and areas designated for cyclists and pedestrians. The Metaurban structure is designed to absorb impacts and deflect vehicles away from pedestrian and cyclist areas, significantly reducing the risk of traffic accidents. Implementing these steel parapets not only improves safety but also offers a sense of protection and peace of mind to all users of the seaside promenade.

Smart solutions for the seaside promenades of the future: a step beyond in terms of road safety.

Preventing accidents is key when planning road safety for the summer season. As mentioned earlier, separating bicycle lanes and pedestrian paths from roads is effective and convenient, but it is even more crucial to prevent these potential accidents through risk detection and signaling to users.

In addition to traditional steel parapets, smart solutions like PLUG&META® are revolutionizing road safety as we know it.

This advanced system incorporates technology that detects and alerts in real-time about potential risks and informs authorities in the event of a serious incident. Thanks to its network of sensors and cameras, it can identify risks such as the presence of pedestrians and cyclists, approaching vehicles at high speed, or situations that may lead to traffic accidents.

Continuous monitoring and immediate response capabilities allow for accident prevention and improved safety on seaside promenades. This enables administrations and municipalities to make mobility decisions based on real data from their roads.

The technology can be applied to any new or existing road element, allowing it to be combined with the Metaurban steel parapet to create the perfect solution for beach areas and seaside promenades.

This summer, it is essential to enjoy outdoor activities safely. The protection of cyclists, pedestrians, and PMV users on seaside promenades should be a priority. Local councils and administrations have the responsibility to implement effective solutions, such as Metaurban steel parapets and active road safety technologies like PLUG&META®, to prevent accidents and ensure everyone's safety.

By taking these measures, we can create safer and more enjoyable environments to enjoy the summer. Safety is everyone's responsibility, and with adequate infrastructure, we can protect tourists and residents, ensuring that our seaside promenades are safe and welcoming spaces for all.

Our International Projects: Ireland

At Metalesa we have always been very clear about our main objective: improving the quality of people’s lives through our protection systems. Our job is to collaborate in the development of infrastructures that allow this goal to be met.

Currently, our areas of activity are: Road Safety, Mobility & Smart City, and Acoustics. In all of them, we are specialized in the development, engineering, manufacture and marketing of products for road, urban and railway equipment.

In addition, our export vocation has allowed us to protect people in different countries. Through the commercialization of our solutions we have been able to carry out the quality of our products to international markets, exporting to more than 40 countries on 4 continents.

Precisely, in today's article we want to talk to you about two of our international projects, specifically some that we have recently concluded in Ireland.

META13 parapet, the most complete containment system in its range

We present two projects with two aspects in common: They are in Ireland and in both cases the infrastructures were equipped with the META13 Parapet, our H2 containment level model

Works were carried out on the N25 New Ross Bypass roads in 2019 (1,1775 meters from META13) and on the M11 Gorey to Enniscorthy in 2018 (220 m from META13). We are very proud that Metalesa has participated in these international projects and that our products are contributing to the improvement of road safety beyond our borders.

We leave you the spectacular images of both projects

N25 New Ross Bypass

N25 New Ross Bypass

M11 Gorey to Enniscorthy

Features of the META13 parapet

The META13 steel parapet is a vehicle containment system designed for installation on the edges of bridge decks, grade-separated crossings, supporting wall crowns, and similar works.The device is approved according to Standard UNE EN 1317 Parts 1 and 2 that, together with compliance with Part 5 regarding production control, has obtained the CE marking.

Something that favors the possibility of installing our parapets in Ireland is precisely the creation of this regulation, since since 2011 it is mandatory that vehicle containment systems installed in the European Union be certified under the UNE EN 1317 standard. sense, the acceptance criteria after passing the rigorous tests to which the parapets are subjected, are the same for the entire European Union.

If you want to know more about the UNE EN 1317 Standard, we recommend you read this article.

Here are some of the advantages of the META13 steel parapet:

- Reliability of the containment system following testing in the worst possible scenario on a cantilevered bridge deck.

- The reduced dynamic deflection DN=0.6 m and the excellent working width WN=0.8 m (W2) of the system mean that it can be installed on supporting elements of optimised dimensions.

- These properties allow for the installation of acoustic screens and vandal-proof fences at very short distances from the parapet.

- System with shear anchor. In the event of a collision, it is rapid, simple and cheap to replace, with no structural alterations to the bridge deck.

- Simple assembly due to its small number of components.

- Can be transformed into an H3 system.

- System versatility, as it can act as both a vehicle and a pedestrian containment system by installing a grille.

- Alternative anchoring systems can be adapted for existing bridges.

- Hot-dip galvanising of all its components according to Standard EN 1461.

- Powder coating in the different standard colours of the RAL chart.

Our vision: an international future

Just as we have our mission clear, our vision too:

"We aspire to become a customer-oriented company with international recognition, anticipating the future of the sector."

And it is that our projects in Ireland are just one example of our commitment to society to get our products to the whole world. We believe that innovation is the key to being able to continue offering the market safer systems with higher performance, for this reason, we have our own R&D team that is responsible for researching and developing new products.

If you want to know more about our international projects, or need to ask us anything about our products, do not hesitate to contact us. We will be happy to help you in your project.

How to make a sports complex look new?

All cities, large or small, have one thing in common: their love for sports. Some of them are capable of hosting many facilities, while some others hardly have a sports hall which they know how to get the most out of. A football, basketball, handball or any other sport team can be something iconic for a city, which is partly due to the sports complex where they train and compete in regional, national and international championships. For this reason, it is becoming more important that sports complexes stand out for their structure and design, and thus generate pride and identification among the population.

As you know, since our very beginning, at Metalesa we have dedicated ourselves to ensure the safety and quality of life of what matters most to us: people. Our products are aimed at both road and urban safety and noise reduction. Therefore, we can get in charge that the sports complex of the clubs of a city have the space they deserve.

How do we help?

We reform and modernize sports complexes with the integration of acoustic screens on its façade. This includes:

- Previous acoustic studies to define parameters to be achieved

- Aesthetics are important. New screens will provide the facilities a facelift that will not go unnoticed: a quality material, striking colours... sports complexes cannot be left behind in our efforts to modernize cities according to our philosophy of creating Smart Cities.

- Noise pollution. Sports complexes are usually a big source of noise, usually generated by a passionate public. In addition, many facilities are also used as concert halls. To handle such challenges, our acoustic screens will be a success to guarantee the rest of the close neighbourhood and comply with the regulations on noise pollution in urban environments.

Acoustic Studies

Any project of such scope must be preceded by an acoustic study according to regulations in force. By using advance technologies, we will get as a result the parameters to be achieved, which will act as input requirements to the optimized constructive solution that must meet them. At Metalesa we have extensive experience in conducting these acoustic studies.

What characterize our acoustic screens to be integrated into sport complexes facades?

Minimizing the noise of sports complexes is possible thanks to the characteristics of our acoustic screens made with sound-absorbing panels:

- Absorbent face oriented to the noise focus: absorbent face is multi-perforated. These perforations make it possible for sound waves to penetrate the panel and dissipate in the absorbent material located inside, thus minimizing noise.

- Acoustic insulation: as an absorbent material, rock wool of different thicknesses and densities is used depending on the acoustic characteristics that must be met. The rock wool is integrated into the interior of the panels, so that a reduction in the sound level is achieved.

- Reflective face: The reflective face leaves a space with the rock wool, generating an acoustic chamber, so that the sound waves are reflected back into the absorbent material.

- Supporting structure: consisting of HEA / HEB type uprights with hot-galvanized welded base plate and thermo lacquered with polyester powder paint. In any case, the supporting structure solution will be adapted to address the particularities and limitations of each project.

Like all our products, metal acoustic screens have been tested under rigorous evaluations to guarantee their acoustic and mechanical behaviour. This evaluation is based on the EN 1793-1 standard, which allows us to obtain the maximum sound absorption and insulation values for the screens we install. Our team of expert engineers and calculators manage all the factors necessary to make the installation of the screens a complete success.

Sport complexes reformed by METALESA

At Metalesa, our commitment to sport is latent. Did you know that we are official sponsors of Atlético Baleares? In addition, we have transformed their football stadium in Mallorca. Here we leave you some photos!

The opening of the Pobla del Duc relief road avoids dangerous routes

METALESA has contributed to improving the safety of the new road that runs parallel to the current CV-611 through the municipal areas of Benigànim, Quatretonda and La Pobla del Duc.

The company took part in this project reconciling one of its main objectives: improving road traffic safety by installing 420m of META13 metal parapets (H2 containment level, a great option among metal parapets), on two bridges of similar characteristics on the Torrella and Forcall ravines with total lengths of 110 and 100 metres respectively. This solved the problem of accessibility and functionality and at the same time provided a greater level of comfort, avoiding dangerous bends for drivers, improving plan and elevation, and reducing travel time.

Another goal was to increase the cross section of the road bed, which facilitates vehicle traffic, and improves the bearing capacity of the road, to achieve a more comfortable journey. It also sought to improve signalling and beacons, longitudinal and transverse drainage infrastructure and its integration into the landscape of the environment.

The work covered the section of 3,179 metres from the existing roundabout on the outskirts of the centre of Benigànim, at PK 4+250, to the roundabout that intersects the CV-611 of the railway station road.

The road has two lanes, one for each direction, a width of 3.5 metres, 1.5 metre hard shoulders on both sides, berms of 0.5 metres and traditional or safety ditches on the side of the clearing.

Keep an eye on our blog to keep up to date with all METALESA’s projects and breakthroughs.

METALESA installs 3km of META16 parapet on viaducts on the A-23

In June 2018, METALESA completed the installation of its META16 parapet with H3 containment level on all the viaducts of the Caldearena-Lanave section of the A-23 between Huesca and Sabiñánigo. In this section, the parapet is concentrated on several overpasses and some landmark viaducts such as Fontanal and the river Guarga.

This project considerable improves road safety as it is a split before the fork of the motorway to bypass the port of Monrepós. Its design also preserves a space of great ecological value in line with the Ministry of Development’s environmental study.

Read more about this news in Heraldo (in Spanish).

Cornices on bridges and viaducts project

Cornices on bridges and viaducts project. Development of multi-purpose systems for the runoff and collection of rainwater and for the channelling of electrical installations.

File No.: IMACPA/2016/174

In October 2016, METALESA S.L. received a subsidy from the Valencian Business Competitiveness Institute (Instituto Valenciano de Competitividad Empresarial - IVACE), specifically the R&D Projects Certification Programme. The aid is funded by the ERDF Operational Programme of the Valencian Community 2014-2020.

Completion of work on the high-speed track line for the San Isidro-Orihuela section (Alicante)

In March 2016 METALESA completed the supply and assembly work on the San Isidro-Orihuela section (Alicante) of the High-Speed Line (AVE). Once again, METALESA successfully completes its work on a landmark project to roll out railway infrastructure in Spain, guaranteeing the use of the best safety equipment.

The elements and distances covered were:

7,200m2 of acoustic screens in viaducts

6,000m of handrails in tunnels

500m of guardrails

300m of vandal-proof fencing

500m of enclosures in the new Callosa de Segura station

This section, 9.6 kilometres in length, is part of the High Speed Line Madrid - Castilla La Mancha - Valencian Community - Region of Murcia, and runs through the municipal areas of San Isidro, Granja de Rocamora, Cox, Callosa de Segura, Redován and Orihuela.

This stretch is part of the route between Monforte del Cid (Alicante) and Murcia, 64.7 kilometres long, and whose contract has already been awarded and is in the execution phase.

From the point of view of efficiency and maximum use of new infrastructure, it is important to note that the new service from Monforte del Cid - Murcia will consist of double standard-gauge track, which will allow commuter services to connect with Alicante, Elche, Orihuela and Murcia.

When all these sections are finished, the hourney times by train between Madrid and Elche, and between Madrid and Murcia, will reduce to 2 hours and 10 minutes, and to 2 hours and 25 minutes, about 30% of the time of going by road.

METALESA continues to offer a quality product in the general interest of Spanish and European citizens, as well as the talent of its team of professionals. Metalesa makes the best road safety equipment available and is firmly committed to continue developing the Spanish and European railway infrastructure network to reduce journey times

METALESA installs its urban parapet in one of the underpasses with a high accident rate in Valencia

In December 2018, METALESA concluded the installation of 800 metres of urban parapet for the Bulevar Sur underpass in front of La Fe. Its objective is to prevent cars crossing the median strip and ending up in the opposite direction, which causes many of the serious accidents that occur at that point.

This median strip is part of the short-term actions to improve road traffic safety, part of 'Improving the urban road network and calming city traffic' strategic approach of the City's Road Safety Master Plan. The Road Safety Master Plan for 2018-2023 is the first prepared by the Valencia City Council and in line with the European Commission’s objective to cut the total number of fatalities on European Union roads in half by 2020 and following the principles of 'Vision Zero', a multinational road safety project that seeks traffic systems without deaths or serious injuries.

Learn more about the project in this news article published in Las Provincias (in Spanish).

METALESA completes the viaduct over the Tajo river of the Madrid-Extremadura high-speed line

In April 2019, METALESA completed work on the Cañaveral-Alcántara Reservoir section of the construction project of the Madrid-Extremadura high-speed line between Tayuela and Cáceres.

This section includes a 1,488 metre long viaduct on the river Tagus, with a signature 324 metre central arch span. At the same time, two bridges have been projected, 162 metres on the Regato de Cuervo and on the 114 metres on the Roman road Vía de la Plata.

https://www.youtube.com/watch?v=pi-UzgrTcfA

METALESA has been responsible for manufacturing and installing all the metal equipment for this section, specifically more than 3,000 metres of bird protection screens, 636 metres of ADIF railings, 226 metres of ADIF vandal-proof fencing and 180 metres of our META16 parapet with H3 containment level for overpasses.

With this project, METALESA further consolidates its position as a leading company in the roll out of the national high-speed network, in which it has been actively involved for many years, through many recent projects in the Basque Y and the Madrid-Galicia line.

Metalesa will be present in flagship project over Cadiz bay

METALESA SV has been awarded 1.250 m2 of noise walls 2.5 m high, of which the first meters is metallic sheet and the rest is methacrylate. This panels will be placed in the section of River San Pedro Industrial Park, reducing the noise from car traffic crossing the new bridge.

Following this awarding, METALESA SV becomes a part of the companies participating in this emblematic project, aimed at improving the access to the city center and improving road communication of the Bay area, contributing to the economic and social development of the city of Cadiz and its port.

The Second Bridge is the most important infrastructure currently under construction in the whole of the European continent. It is the cable-stayed bridge with longest span in the world, overpassing Tianxingzhou Bridge in China (504 meters) and Oresund Bridge that unites Sweden and Denmark (409 meters).