Hot-dip galvanizing: Durability of road safety equipment

Road safety depends on the structural integrity of its devices. From vehicle restraint systems (safety barriers, guardrails, impact attenuators, etc.) to sign gantries and road markings, most of these systems are made of steel. The greatest enemy of steel, especially in environments exposed to the elements and corrosive agents (salt, humidity, pollution), is corrosion. While other solutions such as weathering steel are beginning to be explored, hot-dip galvanizing is undoubtedly the leading solution that guarantees the longevity and consistent performance of the equipment, directly impacting the reduction of maintenance costs for public administrations.

1. Corrosion: The Hidden Cost on Roads

The oxidation of steel is not just an aesthetic problem; it compromises the functional capacity of road equipment. For example, a corroded guardrail can fail to absorb the energy of an impact, endangering the lives of vehicle occupants.

The costs associated with corrosion are divided into two categories:

- Direct maintenance costs: Repair or premature replacement of corroded components, including the cost of personnel, materials, and traffic management during the intervention.

- Indirect safety costs: The risk of equipment failure and the potential increase in accidents if the device does not perform its function.

2. The Hot-Dip Galvanizing Process

Discontinuous hot-dip galvanizing is a metallurgical process in which steel is immersed in a bath of molten zinc at a controlled temperature between 440°C and 500°C. This process not only coats the surface of the steel but also creates an iron-zinc intermetallic alloy metallurgically bonded to the base steel. For this reason, the final result is considered more of an alloy than a simple surface coating.

2.1 Process Phases for Durable Coating

To ensure proper adhesion of the alloy layers, the process follows a strict 10-step sequence before immersion in the zinc bath:

- Receiving and Shipping: Initial inspection of the parts and preparation for the process.

- Acid Degreasing: Removal of grease, oil, and surface dirt using degreasing solutions.

- Pickling: Immersion in acid (generally hydrochloric acid) to remove rust and mill scale, leaving the steel chemically clean.

- Washing: Rinsing to remove surface acid residue before the next phase.

- Fluxing: Immersion in a zinc ammonium chloride solution to prevent premature oxidation of the clean steel and facilitate the metallurgical reaction with the molten zinc.

- Oven Drying: Complete removal of moisture from the fluxed parts to prevent violent splashing upon contact with the molten zinc.

- Furnace Drying: Complete removal of moisture from the fluxed parts to prevent violent splashing upon contact with the molten zinc. Galvanizing: Immersion in a molten zinc bath, where the Fe-Zn alloying reaction occurs.

- Air Cooling: Controlled removal from the zinc bath to allow the coating to solidify and cool.

- Optional Passivation: Post-galvanizing chemical treatment to minimize the formation of "white spots" during storage.

- Refinishing and Shipping: Removal of excess zinc, final thickness inspection according to regulations, and preparation for shipment.

2.2 Protection Mechanisms

Unlike paints or surface coatings, hot-dip galvanizing offers a double layer of protection:

- Physical Barrier: The zinc coating isolates the steel from the corrosive environment (humidity, oxygen, salt).

- Cathodic Protection (Sacrificial): If the zinc layer is damaged (for example, by scratching or impact), the zinc, being more reactive than iron, is sacrificed and corrodes first. This protects the underlying steel from oxidation by healing small damaged areas (the so-called "galvanic cell").

This sacrificial protection is critical for road safety elements that are constantly exposed to abrasion and minor impacts.

3. Durability and Reduced Life Cycle Cost

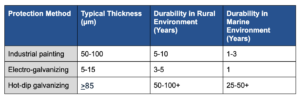

The main advantage of hot-dip galvanizing is its exceptional durability, especially compared to other protection methods (paints or electrolytic zinc coatings).

Hot-dip galvanizing provides, with a single application, protection that can last for more than 50 years in most road environments, resulting in a lower Life Cycle Cost (LCC) for the administration.

3.1 Cost Comparison

The initial cost of a hot-dip galvanized element may be slightly higher than painting, but the need for maintenance is eliminated for decades. If projected over 50 years, the total cost of a painted component (requiring 5-10 repaintings) is up to four times higher than the single cost of the initial galvanizing investment.

4. Regulatory Compliance and Quality Assurance

The effectiveness and reliability of hot-dip galvanizing are regulated by international and European standards that guarantee the performance of products in road infrastructure.

- ISO 1461 / EN ISO 1461: This standard specifies the properties of hot-dip zinc coatings on finished products (including fasteners and road safety components). It establishes the minimum coating thickness requirements, measured in microns (µm), which depend on the thickness of the base steel.

- Visual Finishes and Quality: It is important to note that the final appearance of the galvanized coating may vary (high gloss, crystalline, matte gray). These different shades are characteristic of the process and depend on the chemical composition and reactivity of the steel, as well as the cooling rate. These color variations should not be considered defects, as corrosion resistance remains unchanged. Natural aging over time will homogenize the color.

- CE Marking: In the European Union, road safety devices (such as barriers) must bear the CE marking, which signifies that their manufacture, including anti-corrosion treatment, complies with European performance and durability standards.

By specifying hot-dip galvanizing, authorities not only purchase durability but also ensure compliance with strict safety regulations. Infrastructure protected with this method extends its lifespan, improves safety, and allows managing bodies to redirect resources from corrective maintenance to more strategic investments.

Energy Efficiency in Lighting: The strategy of the State Road Network (RCE)

The State Road Network (RCE), managed by the Directorate-General for Roads (DGC) of the Ministry of Transport and Sustainable Mobility (MITMA), faces an energy challenge of great magnitude. The energy efficiency strategy has become a priority to reduce high operating expenditure and align with the objectives of the ecological transition, based on technological modernization and advanced telemanagement.

1. Context and Magnitude of Energy Expenditure

The RCE's electricity consumption is one of the largest in public administration. Historically, consumption has remained close to 145,000,000 kWh/year, with an associated cost of tens of millions of euros, underscoring the urgency of intervention.

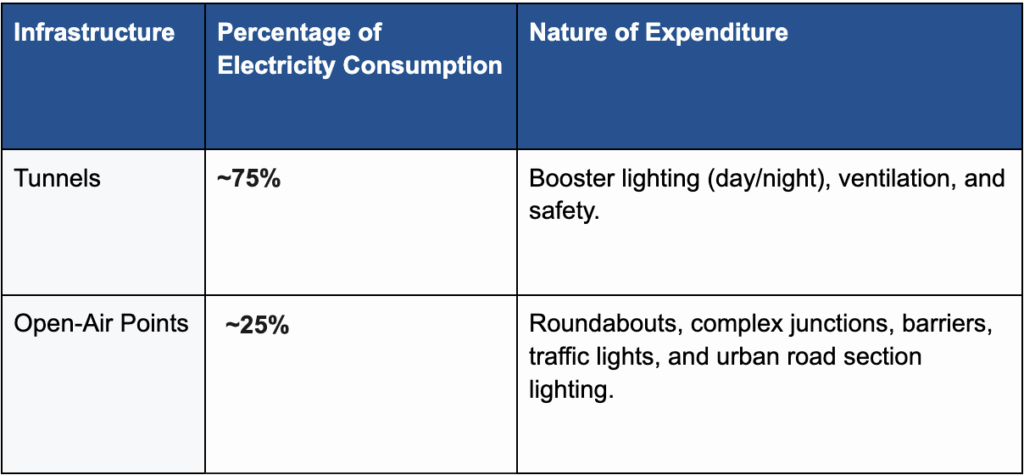

1.1 Critical Distribution of Consumption

The interurban infrastructure shows an unbalanced consumption distribution, primarily concentrated in the lighting and operation of enclosed structures.

This dependence on consumption in tunnels (where lighting and ventilation are vital safety functions that cannot be interrupted) demands solutions of maximum efficiency that do not compromise visibility standards.

2. The Innovation Strategy (CPI) and the Three Lines of Action

The RCE's strategy is articulated around Public Procurement of Innovation (CPI), a mechanism used by MITMA to promote technological solutions addressing its specific needs.

The central goal of the DGC is to achieve savings of between 40% and 50% of the network's total consumption. This is achieved through coordinated action in three fundamental lines of action:

Axis 1: Luminaire Requirements (LED Migration)

The migration from obsolete technologies like high-pressure sodium lamps (VSAP) to LED technology is the first step, but it must meet advanced technical requirements to ensure long-term durability and efficiency in a demanding environment:

- Required Service Life: New luminaires are required to have a very high minimum service life, with certifications such as L90B10_100.000h. This means that only 10% of the units can have depreciated their luminous flux below 90% of their initial value after 100,000 hours of operation.

- Maintenance Reduction: High reliability is key to minimising interventions on the road, which are costly and dangerous.

Axis 2: Telemanagement and Dynamic Control (ITS)

The implementation of an Intelligent Management System (SGI) is essential to achieve savings targets through dynamic light adaptation.

- Standard Connectivity: The control nodes that allow remote monitoring and dynamic adaptation must be of an international standard, integrated using NEMA or Zhaga connectors.

- ITS Functionality: The SGI enables the dynamic adaptation of lighting in real-time to environmental and traffic conditions. During off-peak hours, intensity is reduced to pre-established levels, but the system must be capable of immediate re-activation when vehicles pass or in emergency situations (e.g., an accident warning or fog).

Descriptive Chart: RCE Saving Goal

- Baseline Consumption (Without CPI): 145.000.000 kWh/year

- Saving Target (40%): Reduction of 58.000.000 kWh/year

- Target Consumption: 87.000.000 kWh/year.

Axis 3: Road Safety and Strict Regulatory Compliance

On roads, lighting is a safety factor that must be managed with millimetre precision, especially at high speed. Therefore, regulatory compliance is non-negotiable and becomes the third strategic pillar:

- Luminance vs. Illuminance: Unlike urban roads (where illuminance is measured), on highways, average luminance (Lm) is prioritised, which is the light reflected from the pavement to the driver's eye.

- Requirement Levels: Lighting solutions must guarantee the average luminance levels required by regulations, which range between 0.30 and 2.00 cd/m², depending on the type of road (motorway, conventional) and traffic intensity (IMD).

- Mitigation of Accident Risk: Efficient and reliable management of lighting at singular points is an unavoidable road safety priority. Studies like the one by INTRAS on run-off-road accidents have shown that the lack of lighting is a factor that significantly increases the risk and percentage of night-time accidents, justifying investment in intelligent and reliable systems at points where lighting is legally mandated.

3. Vision 2030: Digital Transformation and Sustainability

Smart road lighting in the RCE is not just a saving measure but a strategic component of the road network's transformation:

- Sustainability: Energy saving contributes directly to the objectives of the RCE's 2030 Energy Efficiency Strategy, minimising energy dependence and reducing the infrastructure's carbon footprint.

- Big Data and ITS Integration: The lighting telemanagement nodes are transformed into a sensor network that can be integrated into the MITMA ITS ecosystem. This allows for the collection of environmental and traffic data at remote points, crucial for predictive infrastructure maintenance and informed decision-making in mobility planning.

In summary, the investment in adaptive lighting for the RCE represents a paradigm shift: from being merely an operating cost, lighting becomes an intelligent management asset that guarantees maximum safety and regulatory compliance with the minimum energy footprint.

Infrastructure management: The challenge of the maintenance backlog and the importance of asset inventory

Road maintenance is a fundamental pillar for ensuring mobility and user safety. However, the sector faces a structural challenge: managing assets that, due to an accumulated investment backlog, require immediate intervention.

Beyond theoretical debates, the operational reality shows that current management must focus on correcting incidents to ensure infrastructure quality. According to the recent Audit by the AEC (Spanish Road Association), the deterioration of functional elements forces a prioritisation of asset repair and replacement to guarantee functionality and extend the product lifecycle.

Below, we analyse the current state of the network and how technology and compliance with road safety regulations are key to recovery.

1. Situation analysis: Impact on road maintenance costs

Technical data reveals a complex scenario. The investment deficit has led to the accelerated ageing of deployed equipment. From a technical perspective, this implies that a large part of the infrastructure has exceeded its optimal service life and cannot be expected to operate with the foreseen performance levels.

Sector studies indicate that postponing corrective intervention multiplies future costs and affects road sustainability. A road without adequate asphalt is not only unsafe but also increases vehicle fuel consumption, raising the infrastructure's carbon footprint. A road with defective road markings and deteriorated vertical signage harms road safety. A road whose restraint systems are obsolete and in poor condition is less prepared to be a "forgiving road".

2. The foundation of efficient management: Inventory and road inspection

In an environment of limited resources, a comprehensive inventory is indispensable. It is not viable to plan without precise knowledge of the installed reality. The trend towards Smart Roads begins by digitising the basics:

-

Georeferencing: Exact location of each asset.

-

Diagnosis: Classifying elements according to their degree of deterioration.

-

Data: Utilising road Big Data to prioritise actions based on technical risk.

3. Critical areas for technical intervention

Safety depends on the correct interaction of all elements. The deficiencies detected require specific actions in four main blocks, always complying with road product certification:

3.1. Pavements and road surfacing The road surface is the element most exposed to wear. A degraded pavement reduces skid resistance and increases the risk of accidents. Its repair is a priority to restore safety and transport efficiency.

3.2. Vertical signage and active road safety Signage has a limited service life. Compliance with night-time visibility regulations is critical. Replacement must ensure the required levels of retroreflectivity, guaranteeing that signs are visible and legible in any condition, acting as true active infrastructure.

3.3. Road markings (horizontal signage) Road markings are fundamental for the human driver, especially on regional roads where there are often more bends and a lack of hard shoulders, vertical signage, or public lighting. Furthermore, even on high-intensity roads, they are fundamental for connected mobility. Driver assistance systems (ADAS) depend on well-painted and maintained lines to operate correctly.

3.4. Safety barriers and advanced restraint systems This is one of the most critical points. The current stock of metal barriers and guardrails presents significant challenges related to obsolescence, lack of performance, protection against corrosion, and damage from previous impacts. In this regard, and to guarantee safety, it is imperative that any replacement or new installation strictly complies with the EN 1317 standard. This implies using restraint devices that have passed the corresponding impact test, ensuring that their dynamic behaviour (working width and containment level) is appropriate for the type of road. Additionally, it is fundamental to consider the durability of metal structures through treatments such as galvanising to withstand weathering.

4. Technology and road sensorisation

The industry is advancing towards predictive maintenance solutions, such as the use of computer vision technologies (whether on-board a vehicle or from the air with drones) or LiDAR. These allow for road inspection at traffic speed, digitising the condition of equipment at very high speed, with maximum precision, and without risk to operatives.

These tools allow administrations to evolve towards more optimised asset and maintenance management, based on data and real-world diagnosis of deployed equipment, optimising every euro invested in road recovery.

Improving road safety requires facing the maintenance backlog with courage and new tools, ensuring that every euro invested is useful. Only in this way will it be possible to return the infrastructure to the quality standards that current mobility demands.

Adaptive lighting: Energy efficiency in Smart Cities and urban roads

Adaptive road lighting stands as a fundamental component for the development of Smart Cities, integrating sustainability and energy efficiency with pedestrian safety and comfort into a single intelligent system. In the urban context, street lighting adjusts its intensity and light pattern based on real-time data, prioritising the specific needs of the city's streets and squares.

This proactive approach responds to the critical need of administrations to reduce high municipal electricity consumption and improve the nocturnal liveability of their environments.

1. Energy efficiency and intelligent consumption management

Outdoor lighting represents one of the largest items of energy expenditure for municipalities, consuming between 40% and 60% of their total electricity. The implementation of adaptive lighting, based on high-efficiency LED luminaires and tele-management systems (LMS – Lighting Management Systems), allows for unprecedented optimisation.

-

Demand management and dynamic dimming: The key strategy is selective dimming. Instead of maintaining constant power throughout the night, light intensity is modulated automatically. During hours of low activity, especially in the early hours of the morning or on secondary streets, power can be reduced to minimum levels of 20-30% of total capacity. It only increases to 100% instantaneously and gradually upon the detection of a pedestrian, cyclist, or vehicle.

-

Sustainable savings and KPIs: This intelligent management can generate energy savings of between 50% and 75% compared to traditional lighting. This saving translates directly into a significant reduction in the municipal carbon footprint, contributing to the UN Sustainable Development Goals (SDGs) and energy transition commitments.

-

Predictive maintenance 4.0: The tele-management of each light point (node) facilitates remote monitoring. The system automatically detects and alerts regarding voltage failures, power variations, or imminent luminaire failures (detection of flickering or low performance). This transforms maintenance from corrective to predictive, optimising human resources and avoiding service interruptions.

2. Road safety and nocturnal risk mitigation

In the urban environment, lighting is a key factor in accident prevention, especially at critical interaction points between vehicles and pedestrians (junctions, zebra crossings, public transport stops). Insufficient lighting not only generates citizen insecurity but also increases the risk of accidents.

The link with risk in the dark: Specialised studies demonstrate the direct relationship between a lack of light and an increase in accident rates. The recent report on accidents caused by running off the road by INTRAS (Institute of Traffic and Road Safety) corroborates this need. Although the study focuses on interurban sections, its conclusions are fundamental: deficient visibility is directly linked to a higher percentage of accidents, with the risk increasing when the road lacks artificial light. Prolonged darkness reduces the driver's perception capacity, especially regarding static objects on the carriageway or stationary vehicles, increasing the probability of head-on collisions or running off the road.

Adaptive lighting in Smart Cities mitigates this risk through:

-

On-demand activation (tactical dimming): By increasing light only in the presence of a user, the system guarantees maximum visibility at the precise moment a potential risk arises.

-

Prioritisation of pedestrians at crossings: Through sensor detection, light intensity over zebra crossings can be increased in a focused manner, protecting the most vulnerable users and giving them visual priority.

-

Comfort and liveability: It generates a sense of safety and well-being, promoting the use of public space and active mobility (pedestrian and cycling) during night hours, a key factor for quality of life in Smart Cities.

3. Lighting as an IoT platform and source of urban Big Data

The true leap in adaptive lighting is its transformative role as an IoT (Internet of Things) platform within Intelligent Transport Systems (ITS). Smart City luminaires no longer just emit light; they act as a dense network of sensors connected to centralised management software.

-

Sensors for mobility management: Lighting nodes equipped with motion sensors, radar, or low-consumption cameras become urban data collection points.

-

Flow Control: They measure traffic density and pedestrian flow in real-time to optimise lighting and generate mobility heatmaps.

-

Integration with Emergency Platforms: The lighting system can connect with the traffic network. If an accident is detected or an emergency vehicle approaches, the lighting in that section automatically increases to improve visibility and clear the road.

-

-

Multi-Purpose Services and connectivity: The lighting infrastructure becomes an essential support for other Smart City services, offering value-added solutions:

-

Environmental monitoring (air quality, noise).

-

Charging points for electric vehicles or bicycles.

-

Hotspots for the deployment of public Wi-Fi or low-power 5G networks.

-

-

Informed planning (Big Data): Anonymous and aggregated data collected by luminaires (pedestrian flow, environmental data, usage patterns) are processed as Big Data for urban planning, helping authorities make precise decisions regarding the design of sustainable infrastructure (location of cycle lanes, changes in transport routes, or reorganisation of public spaces).

4. Environmental sustainability: Reduction of light pollution

A benefit often underestimated in adaptive lighting is its contribution to environmental sustainability, specifically through the reduction of light pollution.

-

Dark skies: By modulating intensity and directing the light beam (thanks to advanced LED optics), light projected towards the sky (upper hemisphere flux) is minimised. This protects nocturnal ecosystems, reduces the impact on fauna (especially birds and insects), and allows citizens to enjoy a less polluted night sky.

-

Spectral adjustment: The ability to select the colour temperature of LED light (generally below 3000K) reduces the emission of blue light, which is the most harmful to human sleep cycles (circadian rhythms) and generates the most light scattering in the atmosphere, contributing to a healthier urban environment.

Intelligent lighting transforms street lighting from a fixed and passive service into a dynamic, efficient, and central element in the digital and sustainable management of Smart Cities.

Road Safety Barriers: Types, Regulations and the Importance of Certification for Public Projects

Road safety barriers, technically called vehicle restraint systems (VRS), are an essential element of modern infrastructure, designed to protect drivers, pedestrians, and cyclists from traffic accidents. Their main function is to reduce the severity of collisions, preventing vehicles from leaving the road or impacting dangerous elements. In Spain and throughout Europe, the assemble of barriers is regulated by strict standards that guarantee their effectiveness and certification, which are key factors for public works projects.

The choice of the right barrier depends on key factors such as road type, traffic volume, the context (urban, interurban, tunnels, bridges), and the containment level required by regulations. The main categories are described below:

Metallic Barriers (Guardrail)

Metallic barriers, also known as guardrails, are usually made of galvanised steel, offering excellent corrosion resistance and extended durability. These flexible systems are engineered to deform on impact, absorbing and dissipating energy to lessen crash forces and reduce the risk of injury to vehicle occupants.

These systems are ideal for standard roads and motorways, especially in sections where a vehicle could leave the roadway towards slopes, embankments, or wooded areas. Their main benefits are their reduced cost, ease of installation and repair, and great versatility. However, a clear safety zone must be maintained behind the barrier to accommodate its deformation (working width).

Concrete Barriers

These barriers are built with reinforced or pre-stressed concrete, and often feature tongue-and-groove joints to improve their continuity. They are rigid systems that barely deform upon impact, as their main function is to contain and redirect the vehicle back onto the carriageway.

They are used on motorways and high-capacity roads, as well as on bridges, viaducts, and in tunnels, where there is no lateral margin for deformation. Their main advantages are their very high durability and the minimal repair needs after an impact. Their main limitation is that they transmit a higher impact severity to vehicle occupants compared to flexible barriers.

Mixed Barriers

Mixed barriers combine a concrete base with metal elements on the top. Their design seeks a balance between rigidity and flexibility, absorbing impact energy to reduce its severity for occupants without losing structural stability.

They are common in urban areas with mixed traffic (heavy and light vehicles) and on high-speed roads near urban centres, but they are falling into disuse because they are not certified systems according to current regulations since 2011. At the time, they addressed some of the shortcomings of concrete barriers, such as their height.

Motorcyclist Protection Systems

The design of conventional barriers, particularly the vertical posts that support them, creates a serious risk to motorcyclists. In a fall, the direct impact of the rider's body or motorcycle against these rigid elements can cause severe or fatal injuries. To mitigate this danger, motorcyclist protection systems (MPS) have been developed: a continuous lower panel installed beneath the guardrail to shield the posts and reduce under-ride and snagging.

These MPS, made from steel, high-resistance polymers or a steel-polymer hybrid, create a smooth and continuous surface that prevents riders from sliding under the barrier and colliding with the posts. In effect, they guide the rider along the barrier, reducing exposure to the most hazardous impact points. They are a priority safety measure on sections with high motorcycle crash rates, dangerous curves, and mountain roads, where the risk of falling is higher. Multiple studies report meaningful reductions in both the frequency and severity of motorcyclist injuries.

Guardrails and Pedestrian Systems

These systems are designed to protect the most vulnerable users—pedestrians and cyclists—and to guide traffic in urban settings. They are made of materials such as steel, aluminium, or methacrylate, and always comply with accessibility requirements and a minimum protection height.

They are installed on pavements alongside heavy traffic roads, on elevated pedestrian crossings, and in urban areas with high pedestrian volumes. Their main advantage is increased road safety for vulnerable users and better organisation of pedestrian flow.

Reference Standards

In the European Union, the EN 1317 standard is the key reference standard governing the characteristics, performance requirements, and tests methods for road safety barriers. It ensures consistent safety criteria across Member Countries, making validation and comparison easier throughout the European market.

The key parameters defined by the standard are:

- Containment level: indicates the barrier's ability to stop vehicles of different masses, at different speeds and impact angles. For example, an H2 level is capable of stopping a 13-tonne bus, while an N2 level applies to 1.5-tonne cars at intermediate speeds. Each country has mechanisms for selecting the containment level for each type of road and its AADT (Average Annual Daily Traffic) and vehicle type.

- Dynamic deflection (D): defines the maximum distance that the front face of the barrier displaces upon impact.

- Working width (W): defines the maximum distance the barrier displaces backwards during an impact. This is crucial to ensure that the vehicle does not hit obstacles, structures, or pedestrians behind the restraint system.

- Vehicle intrusion (Vi): defines where a hypothetical 4-metre truck box would end up after impacting the barrier. This is especially important in structures where this box could hit structural elements, for example, on a cable-stayed bridge.

- Impact severity (A,B,C): assesses occupant protection, measuring the forces acting on the occupant during the collision. A classification A represents the safest level, as it minimises physical damage to passengers.

Passing the EN 1317 tests enables CE marking—mandatory since 2011—for the marketing and installation of road safety barriers on public works. This certification not only confirms compliance with the European test regime, but also supports acceptance by public authorities in tendering and infrastructure approval processes.

Impact Testing and Technical Validation

Before deployment, barriers must undergo full-scale crash tests at accredited laboratories. These tests reproduce controlled crash conditions using vehicles of specified masses, dimensions and speeds, as required by EN 1317.

During the tests, three main aspects are evaluated:

- Containment and redirection capability: the barrier must prevent vehicle penetration or rollover and then redirect the vehicle back towards the carriageway in a controlled manner to minimise secondary risks.

- Dynamic deformation and energy absorption: Measures the barrier’s displacement/deformation and the energy absorbed on impact—critical for defining the safety space (working width) behind the installation.

- Occupant safety and structural integrity: Assesses in-vehicle acceleration/deceleration and the post-impact stability of the barrier. A certified system must protect in the initial crash and retain adequate performance for subsequent impacts until repaired.

Crash test reports are essential for obtaining CE marking and, consequently, for supplying barriers to public projects.

Certification as a Requirement in Public Projects

In public procurement, EN 1317-certified barriers are not optional but a mandatory requirement.

Beyond compliance, certification adds value for companies in the sector, instilling confidence in both public authorities and road users. It also safeguards competitiveness in an increasingly regulated and demanding market.

However, the CE marking granted by this standard is not the only valid tool for evaluating vehicle restraint systems; in fact, it’s not uncommon for uncertified systems to be installed, such as transitions between VRS or barrier terminals. EN 1317 is, above all, a framework to harmonise evaluation across Europe, a considerable challenge, and authorities have not always issued standards covering every type of restraint system. This doesn’t mean these solutions aren’t rigorously assessed; they may be installed when they’re the best fit for the site or when no suitable CE-marked option is available.

Road safety barriers are not merely equipment; they are a strategic element in reducing crashes and protecting lives. Proper selection, installation and certification ensure not only regulatory compliance but also the feasibility of public and private projects. Choosing certified systems is an investment in safety, sustainability and trust.

Metalesa wins the 21st ACEX National Award for Conservation Safety

Metalesa Road Safety has been awarded the 21st ACEX National Conservation Safety Award for its innovative project, "PlugSmart® Pro: Smart Equipment for Preventing and Reporting Road Accidents."

This important recognition, awarded by the Association of Infrastructure Conservation and Operation Companies (ACEX), recognizes initiatives that stand out for their contribution to improving safety in infrastructure maintenance and upkeep operations.

The PlugSmart® Pro project represents a significant advance in the field of road safety, as it combines smart technology with active signaling solutions to detect impacts, alert emergency services, and reduce response times to accidents. This technology, developed by Metalesa's R&D team, allows for rapid response in risky situations, minimizing the consequences for road users and maintenance personnel.

The ACEX National Award jury particularly valued the PlugSmart® Pro system's ability to integrate into current maintenance operations, its potential to reduce accidents, and its positive impact on the efficiency of interventions. It also highlighted its large-scale applicability in the context of road infrastructure modernization.

This recognition represents a significant boost for our innovation strategy aimed at improving safety and sustainability.

At Metalesa, we understand that the future of infrastructure maintenance lies in the incorporation of smart, connected, and efficient solutions, and this award encourages us to continue moving forward in that direction.

We thank ACEX for the distinction and congratulate the entire Metalesa team that made this milestone possible. This achievement reflects the collaborative work, long-term vision, and firm commitment to road safety that characterizes us.

Road Safety and Accident Prevention: 21st Century Infrastructure

Road Safety and Accident Prevention: The Need for Adaptation and Road Safety

For decades, our roads have been the pillars of mobility, connecting cities, towns, and communities. However, as we move towards an increasingly digital and sustainability-oriented future, it becomes evident that our road infrastructure urgently needs an update. While efforts have been made to maintain and repair existing roads, not enough has been done to adapt them to new mobility methods, Smart Cities, and the growing demands of an ever-increasing population.

The need for infrastructure adaptation to cities

The world is changing at a dizzying pace, and our cities must keep up. Cities are evolving into smarter environments where technology plays a fundamental role in traffic management, road safety, and energy efficiency. However, our urban roads remain largely analog in a digital world. An updated road infrastructure is needed that integrates technologies such as smart sensors, traffic management systems, and vehicular communications to improve traffic flow and reduce accidents. Administrations are aware of this issue and have been implementing data-driven strategies for years to improve citizens' lives.

Sustainable mobility

Sustainable mobility is another crucial aspect that our roads must address. With increasing environmental awareness and the need to reduce carbon emissions, it is imperative to promote the use of public transportation, bicycles, and electric vehicles. However, current roads are not designed to accommodate this diversity of mobility options. Safe bike lanes, charging stations for electric vehicles, and infrastructure that fosters efficient public transportation are needed.

Population growth and urbanization are global trends that are putting increasing pressure on our roads. Cities are more populated than ever, meaning more vehicles on the roads and greater infrastructure demands. However, many of our roads were not designed to handle this volume of traffic, resulting in congestion, longer travel times, and increased pollution. It is essential to adapt our roads to meet the needs of 21st-century cities and beyond.

Road safety and accident prevention

One of the most critical aspects when talking about road infrastructure is the safety of its users. Every year, thousands of lives are lost in traffic accidents, and many more people are seriously injured. It is crucial that our roads are designed with a focus on road safety to reduce these tragedies.

Technology plays a fundamental role in accident prevention. Advanced driver assistance systems, such as automatic emergency braking and blind-spot detection, can help avoid collisions before they occur. Additionally, adequate lighting, clear signage, and regular infrastructure maintenance can improve visibility and reduce risks for drivers.

Technologies like PLUG&META® are a clear example of innovation in the field of SMART ROADS and a clear trend that reaffirms the administration's commitment to the new era. The most appropriate decisions for urban mobility must always be based on real data to ensure the safety of all road users.

Road education also plays a crucial role in accident prevention. Awareness programs about the importance of wearing seat belts, respecting speed limits, and avoiding distractions while driving are fundamental to promoting a culture of safety on our roads.

At Metalesa, we firmly believe that accident prevention requires a holistic approach that addresses both technological and human aspects of road safety. By investing in safer infrastructures and promoting responsible behavior from road users, we can work towards drastically reducing the number of accidents and saving lives on our roads.

Collaboration between the private sector and the administration

Addressing these challenges requires close collaboration between the private sector and public administration. Technology companies can bring expertise in innovation and the development of smart solutions, while governments have the power to establish policies and regulations that encourage investment in road infrastructure. It is crucial for both parties to work together to ensure the safety, mobility, and well-being of everyone who depends on our roads.

In summary, our roads need an urgent renovation to adapt to the demands of the modern world. From integrating smart technologies to promoting sustainable mobility and managing urban growth, many aspects must be addressed. Only through effective collaboration between the private sector and public administration can we ensure that our roads are prepared to meet the needs of Smart Roads in the smart cities of the present and future.

Eco-goals: our sustainable contribution

Welcome to the heart of Metalesa, where sustainability is not just a goal, it is our unwavering commitment! In this article, we will look at the Eco-Targets, the four pillars that guide our mission to be leaders in environmental and social responsibility.

Solar panels: clean energy for a sustainable future

Every action counts, and at Metalesa, we are committed to significant change through solar energy. Our facilities are equipped with solar panels that capture sunlight and transform it into clean electricity. This step towards energy self-sufficiency not only reduces our carbon footprint, but also propels us towards a more sustainable tomorrow.

Did you know that thanks to our solar panels, we have covered 39.6% of our consumption needs and reduced our dependence on non-renewable sources? This investment in green technology is a testament to our commitment to the environment.

Additional benefits of solar panels

Exploring the use of solar panels goes beyond simply adopting a clean energy source; it involves immersing oneself in a series of impactful benefits that impact various aspects of our society and environment. Let's take a closer look at these additional benefits, understanding how solar panels are a comprehensive solution with significant positive impacts:

- Reducing greenhouse gas emissions: By going solar, we make a significant contribution to reducing greenhouse gas emissions, a crucial factor in climate change. Solar panels generate electricity without releasing carbon dioxide or other harmful air pollutants. This approach offers a route to a cleaner and more sustainable environment, making a direct contribution to the fight against climate change.

- Energy independence and long-term stability: Dependence on non-renewable energy sources exposes societies to fluctuating oil prices and energy crises. By incorporating solar panels, greater energy independence is achieved by harnessing an inexhaustible and free source: solar radiation. This independence not only ensures long-term stability in energy supply, but also reduces vulnerability to fluctuations in the global energy market, providing a path to long-term sustainability.

- Contribution to global awareness of renewable energy: By adopting solar energy technologies, we actively participate in creating global awareness of the importance of renewable energy sources. Solar panels are not only a practical solution on an individual or corporate level, but also serve as a beacon to inspire others to follow the path of sustainability. This contribution goes beyond the production of electricity, extending to the creation of a global community committed to a greener and healthier future.

Using recyclable materials: forging a circular future

At Metalesa, the excellence of our products is not only about quality, but also about environmental responsibility. In the manufacture of every item, we are committed to using recyclable materials, thus driving the creation of a circular future and significantly minimising our impact on the environment.

This conscious choice means much more than just producing durable goods. By opting for Metalesa products, you are making a decision to support solutions that go beyond your individual needs; you are supporting the preservation of our planet. Our unwavering dedication to recycling is not simply a duty we fulfil, it is a promise we seal with every product that leaves our facility.

Imagine a world where every product not only serves its purpose, but also contributes to a sustainable cycle. At Metalesa, we're not just building products, we're building a future where responsibility and quality are intertwined to form a lasting commitment to the health of our planet.

Sustainable innovation in our commercial fleet: towards electrification

At Metalesa, we strive to not only deliver quality products, but to do so in a sustainable manner. Have you ever wondered how we achieve this balance? The answer lies in our commercial fleet, a tangible manifestation of our commitment to electrification and the reduction of pollutant gas emissions.

Our fleet, your benefits:

We explore the salient details that make our fleet a model of sustainability:

- Hybrid vehicles: By opting for electrification, we have incorporated hybrid vehicles into our fleet. These vehicles not only consume less fuel, but also emit less polluting gases, marking a firm step towards reducing our carbon footprint. Every delivery we make becomes a conscious act towards a healthier environment.

- Advanced technology: We don't stop at electrification; we have integrated advanced technology into our fleet to maximise efficiency. Real-time tracking of our routes ensures that every journey is planned as efficiently as possible, reducing unnecessary driving times and further minimising our environmental impact.

- Constant innovation: Innovation is part of our identity. We constantly explore options to improve our fleet and thus our contribution to sustainability. From evaluating new technologies to sourcing alternative fuels, we are in a continuous search for greener and more efficient methods for our delivery operations.

Every delivery we make is not just a product arriving at its destination; it is a step towards a more sustainable and environmentally friendly business model. At Metalesa, we are moving towards electrification in the knowledge that every choice counts in building a future where innovation and sustainability go hand in hand.

Zero discharge wastewater treatment plant: taking care of our water resources

Our responsibility is not limited to air and land; we also embrace water. We operate a zero discharge wastewater treatment plant, ensuring that our production processes do not negatively affect the quality of nearby water resources.

How does this contribute to general well-being?

- Water conservation: We avoid contamination of local sources.

- Community engagement: Our responsibility to those around us.

- Transparency: Accessible information about our practices.

Join us on the road to a sustainable future

At Metalesa, every action we take is driven by the desire to contribute to a more sustainable world. Our Eco-Targets are more than just goals; they are the core of our identity and the engine that drives our commitment to sustainability.

Ready to be part of the sustainable revolution? Join us on this journey and choose products that not only meet your expectations, but also contribute to a greener, healthier planet.

Frequently asked questions:

- How do solar panels contribute to sustainability? Solar panels capture the sun's energy and convert it into electricity, reducing dependence on non-renewable sources and reducing greenhouse gas emissions.

- Why is it important to recycle in the manufacture of products? Using recyclable materials in manufacturing helps reduce demand for natural resources and minimises waste generation, thus contributing to building a more sustainable future.

- How can I contribute to zero landfill? As a consumer, you can choose to support companies committed to sustainability and responsible water management, such as Metalesa. By doing so, you indirectly contribute to the goal of zero landfill.

Act today for a more sustainable tomorrow! Explore our product range and choose sustainability in every purchase. Together, we can build a greener, healthier world.

Changes in the regulations on barrier transitions and terminals

When talking about vehicle containment systems, the first thing that comes to mind are safety barriers and parapets. These linear elements are installed on the edges of roads to prevent vehicles from leaving the road and causing serious accidents. Although these are the first that come to mind, there are also other types of vehicle containment systems, such as impact attenuators, transitions between systems, barrier terminals, removable barrier sections and protection systems. of motorcyclists.

All of these systems are regulated by different European regulations that establish the requirements that must be met to be classified in one of the categories contemplated by said regulations. In the case of transitions and barrier terminals, the reference standard is UNE-ENV 1317-4:2002 and in this article we want to talk to you in a little more detail about the changes that are to come.

This standard, which has been in force since April 30, 2002, has never been harmonized by UNE-EN 1317-5:2008+A2:2012. This means that any Transition or Terminal that meets the tests specified in said standard will be accepted, but will not have the CE marking. Therefore, this standard is voluntary and there is no clear impulse on the part of the administrations to require this type of products evaluated under the protection of this standard.

This situation gives rise to points on the State Highway Network that are not well resolved and that can cause serious accidents.

The need to modify this regulation

The European standardization committee “CEN/TC 226/WG 1 – Crash barriers, safety fences, guard rails and bridge parapets” is responsible for preparing regulations relating to the field of vehicle containment systems. The CTN 135 Road Signage Equipment Committee hangs directly from this committee. SC1 Safety Barriers, of which the Metalesa team is a member.

For years, work has been going on within TC226 to modify the UNE-ENV 1317-4:2002 regulations to somehow remove the vehicle containment systems it regulates from the regulatory block. However, to date this task had not been achieved successfully as it was a complex task.

Transitions and terminals, by definition, connect to other systems. A transition is a longitudinal section that joins two systems, such as barriers or parapets, using special pieces that guarantee a logical transition of rigidities. A barrier terminal is a point system, such as an impact attenuator, that connects to a barrier or parapet. Therefore, the evaluation of a barrier terminal involves evaluating the connection between the barrier or parapet and the terminal, which is equivalent to evaluating a transition between systems, even if one of them is not a barrier or parapet.

When it comes to harmonizing these systems under the same standard, there is a big step that must be overcome: there are a multitude of barriers, parapets and terminals on the market that, as we have said before, comply with the regulations but do not have CE marking, which which makes it tremendously complex to establish clear rules to evaluate them and not limit free competition.

New regulations on transitions and barrier terminals on the way

Once the variability in this type of products is understood, it is understood how complex it is to regulate them, however, last June the deadline for voting in TC226 ended. This vote examined the publication of reports and technical specifications that establish the evaluation methods of each of these systems separately and facilitate administrations in establishing criteria to demand the different benefits of the systems, definitively separating them from the marking. EC.

The new regulations of these systems would be as follows:

- Barrier terminals are regulated by FprCEN/TS 1317-7. It is a technical specification, so every 3 years it is decided whether it becomes a standard to be harmonized and be able to have the CE marking.

- Transitions are regulated by FprCEN/TR 1317-10. In this case it is a Technical Report, that is, it does not have to be reviewed at any time, being a declaration of intentions regarding the fact that the transitions will not have CE marking.

With this change in the paradigm of the regulations of Barrier Terminals and Transitions, administrations no longer have to demand a CE marking that could not be obtained, since UNE-ENV 1317-4:2002 is repealed.

Finally, it should be noted that now it is the turn of the administrations to pick up the gauntlet and establish what tests or requirements are required for this type of products to be installed on the roads they regulate. Some administrations, such as the French one, have already championed this change and have requirements aligned with the new regulations.

United Nations World Road Safety Week

Like every year, the third week of May marks the United Nations World Road Safety Week, an event that wants to put in the spotlight the various dangers that exist on the roads to create awareness, thus serving as a loudspeaker for developing regulations that help reduce incidents and save lives.

Last year, a campaign was launched under the slogan #StreetsForLife #Love30. The goal was to create residential urban areas with a speed limit of 30km/h, thus contributing to make cities safer, more ecological and suitable for different mobility models, vehicles, scooters, bicycles and VMPs.

This was the first of many campaigns that have been planned as part of the Decade of Action for Road Safety 2021-2030. This action plan is part of the 2030 Agenda for Sustainable Development, a worldwide voluntary action plan agreed upon by the Member States of the United Nations to protect the planet and all of us who inhabit it, and which seeks, among many other sustainability objectives, to be able to prevent at least 50% of traffic accidents by 2030.

This is more urgent than ever because recent studies speak out about worrying trends. According to Fundación Linea Directa, "the urban accident rate among vulnerable users could worsen, causing up to 5,500 deaths in Spanish cities by 2030, which represents an annual increase of between 30 and 50%". Among the main arguments that the study exposes are the massive deployment of bike lanes in urban environments, the popularity of VMPs, or the lack of social awareness of sustainable mobility.

The new models of urban mobility, a new need

Within the objectives of the 2030 Agenda, special emphasis is placed on the concept of Sustainable Cities: large human settlements in which resource consumption is sustainable without harming air quality. This is why in recent years awareness campaigns have been designed towards more sustainable mobility inside and outside urban areas with the creation of Low Emission Zones and the expansion of pedestrian and bicycle lanes.

With all this, new means of personal mobility have emerged and regulations have become obsolete or have had to be adapted, thus giving rise to new needs in road safety systems.

First approved parapet with active safety

Metalesa's mission is to protect people, it is to save lives. Uniting this purpose with this context of new mobility in urban environments, the idea arose of creating the new Metaurban® SMART, the first parapet with active road safety, that is, it not only passively waits to contain an accident, but also prevents these happen through intelligent signage.

The development of this new product responds to society's growing need to have approved products as a guarantee of quality for urban and peri-urban areas, while taking advantage of new technologies and the deployment of 5G communications to bring containment to a new dimension as smart products.

It is a system fully aligned with the new trends in infrastructure management: security, sustainability and connectivity.

- It guarantees safety because it has been tested on a real scale as certified by the CE marking.

- It promotes sustainable mobility by making the new infrastructures in cities safer and friendlier.

- It is connectable because it integrates PLUG&META® technology, which not only waits for the accident to happen, but also identifies risk situations, and acts by alerting road users through signalling, minimizing the probability that these accidents will happen. Up to 10 functional scenarios have been developed, for example, accident warning, pedestrian presence, excessive speed, traffic jams, or bad visibility warning, among others.

It is a totally innovative parapet because, as can be seen, in addition to containing it in the event of an accident, it prevents these from happening, and also collects data and informs the municipal authority of all those events that are desired, from quality data of air, counting or multiple statistics of events detected by the sensors incorporated in the parapet.

The system is modular, in such a way that SMART technology can be incorporated only in that section where there really is a special need, and the rest can be a traditional containment system that is 100% safe before leaving the track.

And all of this can be managed remotely thanks to the management platform accessible from any device.

In this way, a traditional containment system has evolved into a new traffic management and urban mobility and information service for the city.

The Metaurban® SMART parapet represents a breakthrough in the urban equipment sector, prompting the imagination of how the IoT can transform static elements into active digital members of the smart city ecosystem.

Our goal is to improve people's quality of life, focusing our efforts on offering a range of technologically advanced security and protection solutions. If you want to know a little more about this technology, visit our new microsite.