Road safety depends on the structural integrity of its devices. From vehicle restraint systems (safety barriers, guardrails, impact attenuators, etc.) to sign gantries and road markings, most of these systems are made of steel. The greatest enemy of steel, especially in environments exposed to the elements and corrosive agents (salt, humidity, pollution), is corrosion. While other solutions such as weathering steel are beginning to be explored, hot-dip galvanizing is undoubtedly the leading solution that guarantees the longevity and consistent performance of the equipment, directly impacting the reduction of maintenance costs for public administrations.

1. Corrosion: The Hidden Cost on Roads

The oxidation of steel is not just an aesthetic problem; it compromises the functional capacity of road equipment. For example, a corroded guardrail can fail to absorb the energy of an impact, endangering the lives of vehicle occupants.

The costs associated with corrosion are divided into two categories:

- Direct maintenance costs: Repair or premature replacement of corroded components, including the cost of personnel, materials, and traffic management during the intervention.

- Indirect safety costs: The risk of equipment failure and the potential increase in accidents if the device does not perform its function.

2. The Hot-Dip Galvanizing Process

Discontinuous hot-dip galvanizing is a metallurgical process in which steel is immersed in a bath of molten zinc at a controlled temperature between 440°C and 500°C. This process not only coats the surface of the steel but also creates an iron-zinc intermetallic alloy metallurgically bonded to the base steel. For this reason, the final result is considered more of an alloy than a simple surface coating.

2.1 Process Phases for Durable Coating

To ensure proper adhesion of the alloy layers, the process follows a strict 10-step sequence before immersion in the zinc bath:

- Receiving and Shipping: Initial inspection of the parts and preparation for the process.

- Acid Degreasing: Removal of grease, oil, and surface dirt using degreasing solutions.

- Pickling: Immersion in acid (generally hydrochloric acid) to remove rust and mill scale, leaving the steel chemically clean.

- Washing: Rinsing to remove surface acid residue before the next phase.

- Fluxing: Immersion in a zinc ammonium chloride solution to prevent premature oxidation of the clean steel and facilitate the metallurgical reaction with the molten zinc.

- Oven Drying: Complete removal of moisture from the fluxed parts to prevent violent splashing upon contact with the molten zinc.

- Furnace Drying: Complete removal of moisture from the fluxed parts to prevent violent splashing upon contact with the molten zinc. Galvanizing: Immersion in a molten zinc bath, where the Fe-Zn alloying reaction occurs.

- Air Cooling: Controlled removal from the zinc bath to allow the coating to solidify and cool.

- Optional Passivation: Post-galvanizing chemical treatment to minimize the formation of “white spots” during storage.

- Refinishing and Shipping: Removal of excess zinc, final thickness inspection according to regulations, and preparation for shipment.

2.2 Protection Mechanisms

Unlike paints or surface coatings, hot-dip galvanizing offers a double layer of protection:

- Physical Barrier: The zinc coating isolates the steel from the corrosive environment (humidity, oxygen, salt).

- Cathodic Protection (Sacrificial): If the zinc layer is damaged (for example, by scratching or impact), the zinc, being more reactive than iron, is sacrificed and corrodes first. This protects the underlying steel from oxidation by healing small damaged areas (the so-called “galvanic cell”).

This sacrificial protection is critical for road safety elements that are constantly exposed to abrasion and minor impacts.

3. Durability and Reduced Life Cycle Cost

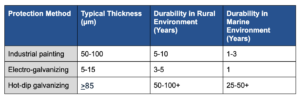

The main advantage of hot-dip galvanizing is its exceptional durability, especially compared to other protection methods (paints or electrolytic zinc coatings).

Hot-dip galvanizing provides, with a single application, protection that can last for more than 50 years in most road environments, resulting in a lower Life Cycle Cost (LCC) for the administration.

3.1 Cost Comparison

The initial cost of a hot-dip galvanized element may be slightly higher than painting, but the need for maintenance is eliminated for decades. If projected over 50 years, the total cost of a painted component (requiring 5-10 repaintings) is up to four times higher than the single cost of the initial galvanizing investment.

4. Regulatory Compliance and Quality Assurance

The effectiveness and reliability of hot-dip galvanizing are regulated by international and European standards that guarantee the performance of products in road infrastructure.

- ISO 1461 / EN ISO 1461: This standard specifies the properties of hot-dip zinc coatings on finished products (including fasteners and road safety components). It establishes the minimum coating thickness requirements, measured in microns (µm), which depend on the thickness of the base steel.

- Visual Finishes and Quality: It is important to note that the final appearance of the galvanized coating may vary (high gloss, crystalline, matte gray). These different shades are characteristic of the process and depend on the chemical composition and reactivity of the steel, as well as the cooling rate. These color variations should not be considered defects, as corrosion resistance remains unchanged. Natural aging over time will homogenize the color.

- CE Marking: In the European Union, road safety devices (such as barriers) must bear the CE marking, which signifies that their manufacture, including anti-corrosion treatment, complies with European performance and durability standards.

By specifying hot-dip galvanizing, authorities not only purchase durability but also ensure compliance with strict safety regulations. Infrastructure protected with this method extends its lifespan, improves safety, and allows managing bodies to redirect resources from corrective maintenance to more strategic investments.