Description

Anti-corrosion treatments consist of the application of a coating that protects the parts from direct contact with oxygen and other components that may rust them.

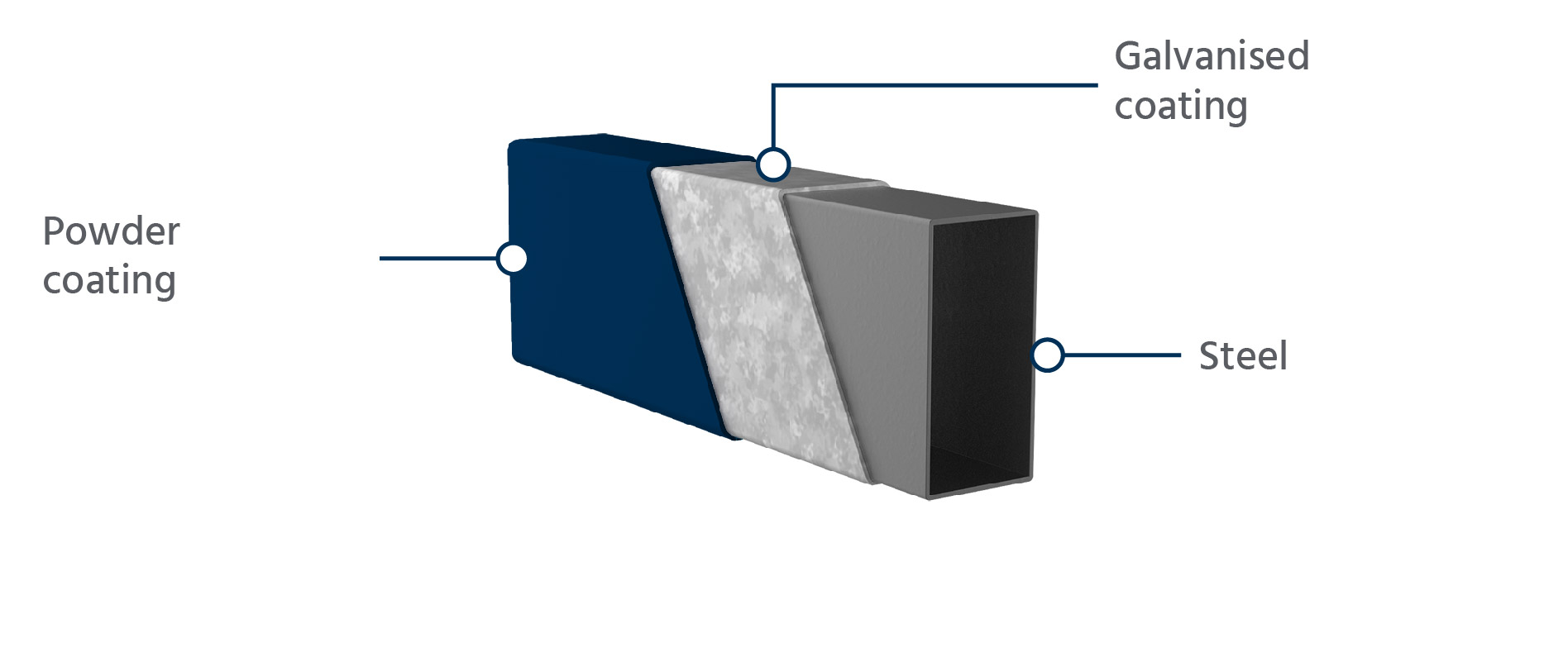

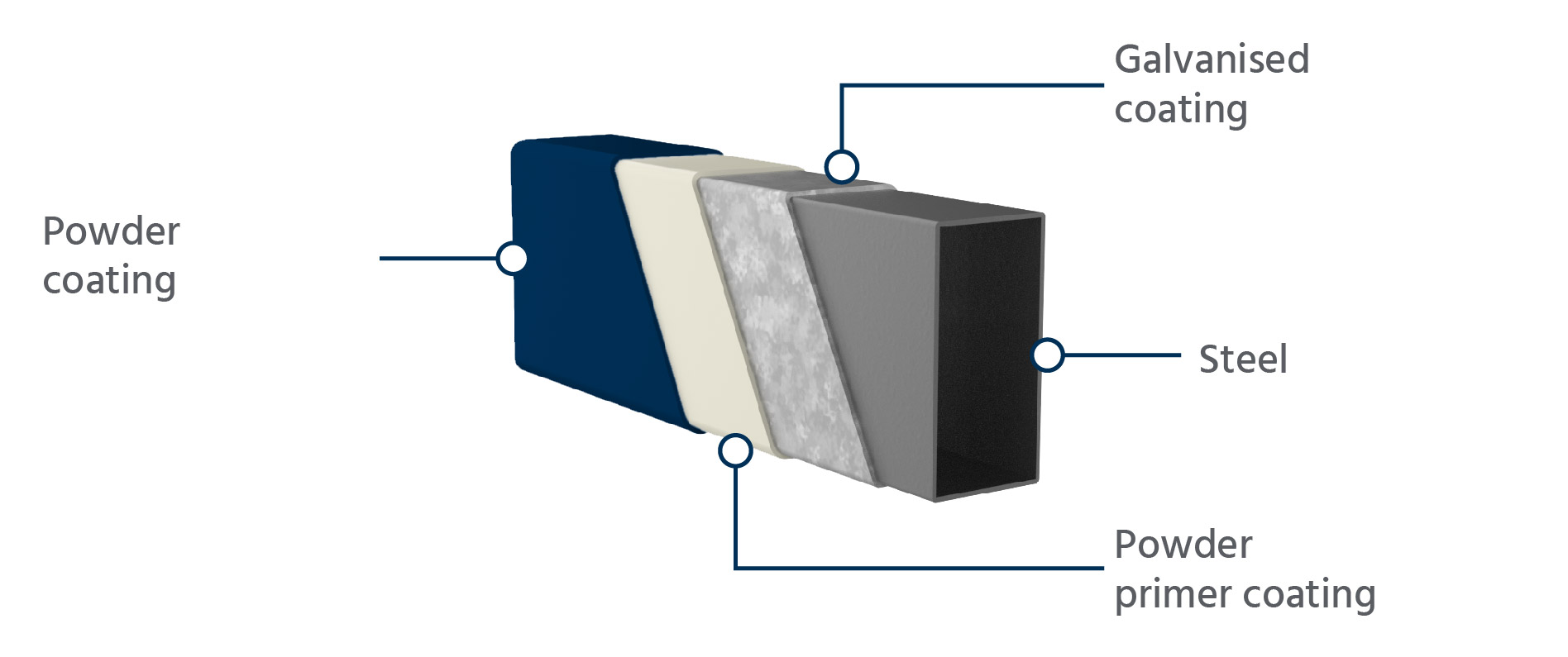

The system consists of hot-dip galvanising the steel and then applying a layer of thermosetting powder paint.

Hot-dip galvanising is a corrosion protection process for materials and articles made of iron or steel, which consists of immersing them in a bath of molten zinc. In this process, protective coatings of zinc and zinc alloys are formed on these materials which are perfectly adhered to the base substrate by means of a metallurgical bond.

In the powder coating process, the powder coating is specially developed to provide high resistance to corrosion and UV radiation, as well as high mechanical strength.

Corrosivity categories according to atmospheric environments

The degree of protection is determined by the type of environment to which the metal part will be exposed according to UNE EN 12944 parts 1 and 2

*C4: Industrial areas and coastal areas with moderate salinity

**C5-I: Industrial areas with high humidity and aggressive atmospheres

**C5-M: Coastal and maritime areas with high salinity

Main advantage: increase the service life of the metal part.

Treatments considered as very efficient to increase the useful life of steel in corrosive environments due to the presence of chlorides and humidity in coastal or maritime areas or by chemical agents in urban and industrial areas.

The primer coat provides additional protection by obtaining greater resistance to particle impact, better adhesion and increased durability.

Industrial application of organic powder coatings on hot-dip galvanised or sherardised steel articles. Specifications, recommendations and guidelines.

Applied process based on the European quality mark QUALISTEELCOAT

Paints and varnishes. Corrosion protection of steel structures by means of protective paint systems – Part 5: Protective paint systems (ISO 12944-5:2019). Protective paint systems – Part 5: Protective paint systems (ISO 12944-5:2019) This is the first publication

Hot-dip galvanising coatings for iron and steel parts – Specification and test methods (ISO 1461:2009) EN ISO 1461:2009 Electroplating of iron and steel – Specifications and test methods (ISO 1461:2009)

Would you be interested to see our products?

We advise you without obligation