Vehicle Containment Systems (VCS) are undoubtedly one of the key elements when it comes to measuring the level of road safety on our road network. These systems, if installed with the appropriate quality standards, significantly reduce the consequences of accidents, mainly off-road or frontal impacts.

There are many national and international regulations that allow the evaluation and certification of products, and that establish a guide of criteria to install them properly, always according to the characteristics of the road and the prescriptions of its manufacturer.

Regulations for vehicle containment systems

The applicable regulation in Europe is UNE EN 1317, which includes several parts with which to evaluate barriers, parapets, crash cushions, transitions between VCS, barrier terminals, removable barrier sections, as well as motorcyclist protection systems. Once established throughout the common European area, each administration must transpose these guidelines by adding its own local criteria. In the case of the Spanish administration, installation criteria for vehicle containment systems is defined in the 35/2014 Circular Order.

This regulation applies in the National Roads Network establishing installation criteria mainly for both barriers and bridge parapets. However, if you are looking for installation criteria for crash cushions or terminals, you will hardly find any reference in article 6.6 where terminals are mentioned as barrier ends, in articles 6.7.3 and 6.7.4 where their differences are mixed, and finally, in article 9, where they are once again mixed up without clarifying when to use one or the other.

Crash cushions have CE marking because part 3 of EN 1317 is harmonized by part 5. However, the terminals do not have CE marking as they are not harmonized by that part 5.

Terminal and Impact Attenuator Performance Levels

Additionally, these systems are classified according to their level of behaviour:

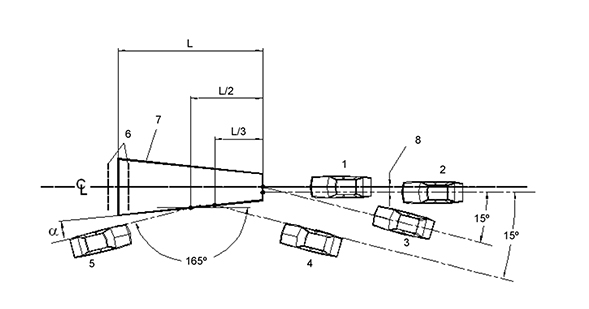

- The Crash Cushions can be of classified as Behaviour Level 50, 80, 100 and 110. This number refers to the speed at which they are tested. For each level, the standard provides for 5 full-scale tests with different directions and angles of approach.

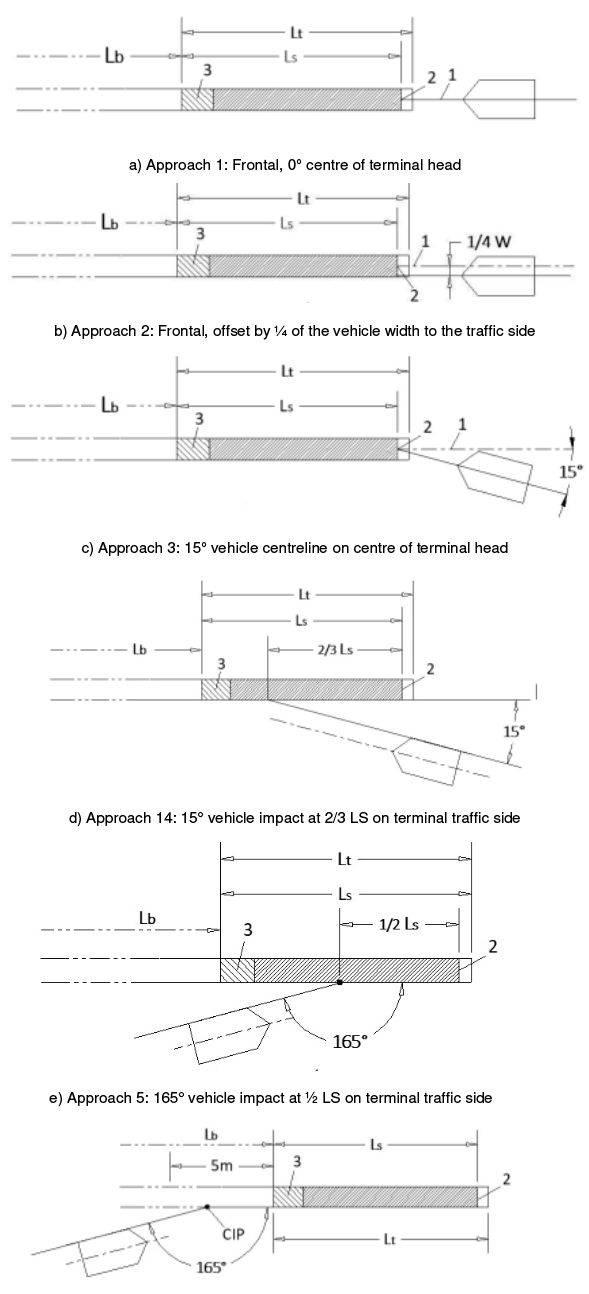

- The Barrier Terminals are currently classified by their Class of Behaviour P1, P2, P3 and P4 according to part 4 of the standard. This part 4 is valid, but it is expected to be imminently replaced by a new Technical Specification for Barrier Terminals recently approved by the Standardization Committee. In this TS, the Terminals are classified differently, as T50, T80, T100 and T110, which is a very similar classification to that of the crash cushions. As for the full-scale tests, up to 6 tests are contemplated to evaluate their behaviour.

All these tests make it possible to characterize the crash cushions and barrier terminals, assigning them deformation parameters associated with the displacements that have occurred in the test itself, as well as severity values for the vehicle occupants.

Criteria for application of Crash Cushions and Barrier Terminals

As seen, the European regulations brings some light to these road safety systems, but when it comes to the actual project on site, where the variety of scenarios is very wide, OC 35/2014 lacks criteria about when using terminals and/or crash cushions, compared to the exhaustive detail of barriers and parapets. For example, in the case of barriers and bridge parapets we can define what level of behaviour is required depending on the severity of the accident and the characteristics of the road. However, in the case of terminals and crash cushions there is no common criteria that guides the choice of the system. One option is to choose the system based on the speed of the track and the speed at which the system was tested. Curiously, this criterion is not the one applied to barriers or bridge parapets, where it is common to install a parapet tested at 70 km/h on a road where driving at 120 km/h is allowed.

Another common point of installation of barrier terminals and crash cushions is in divergences. Once again, the OC lacks installation criteria in these locations, a problem that raises many questions. For example, which road branch to prioritize and whether or not the shoulders of both branches have to be respected, or, for example, the position of the system on the crossroads, more or less away from the vertex of the divergence. In this case, it will be necessary to assess how much barriers of both branches can converge.

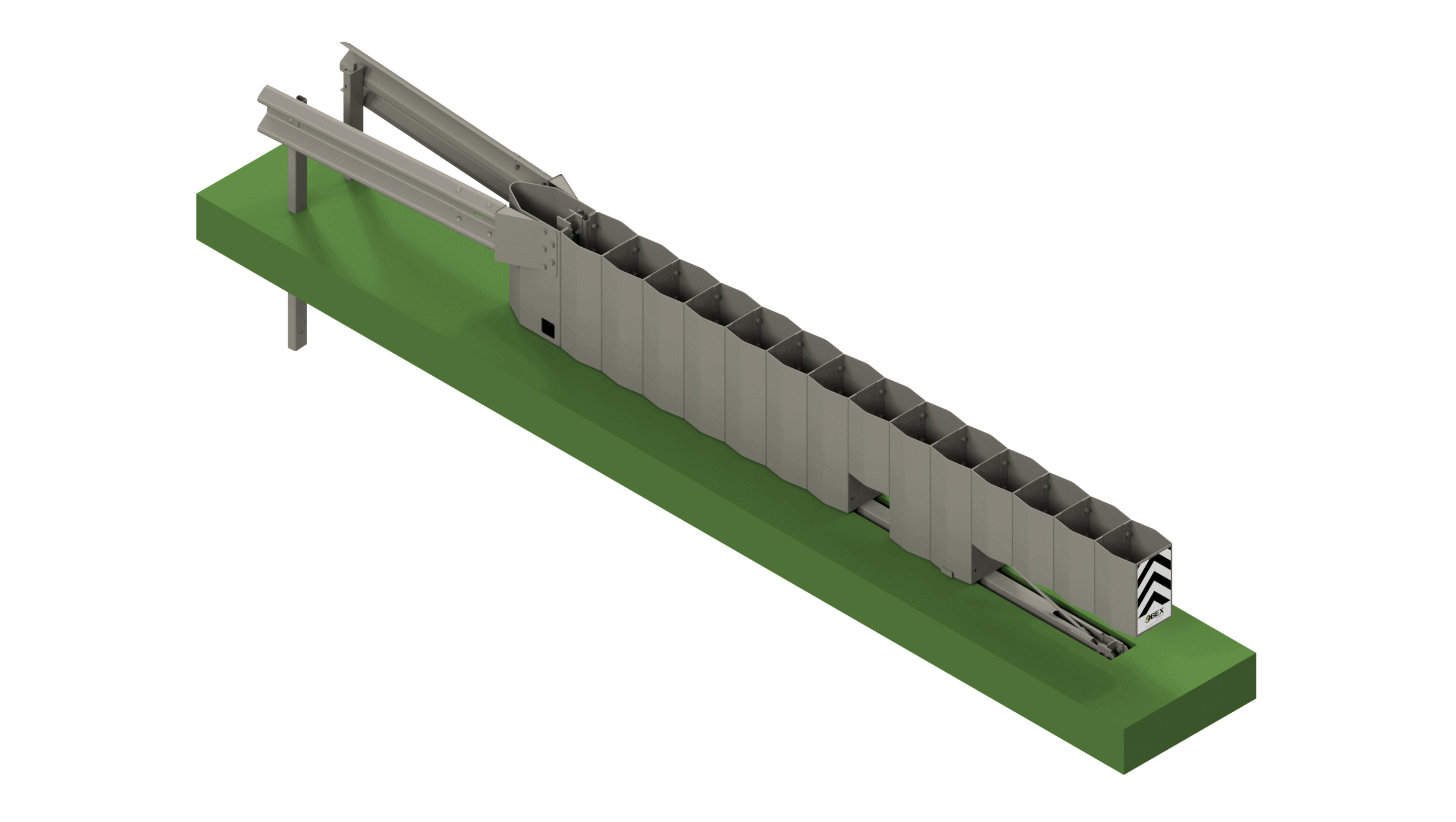

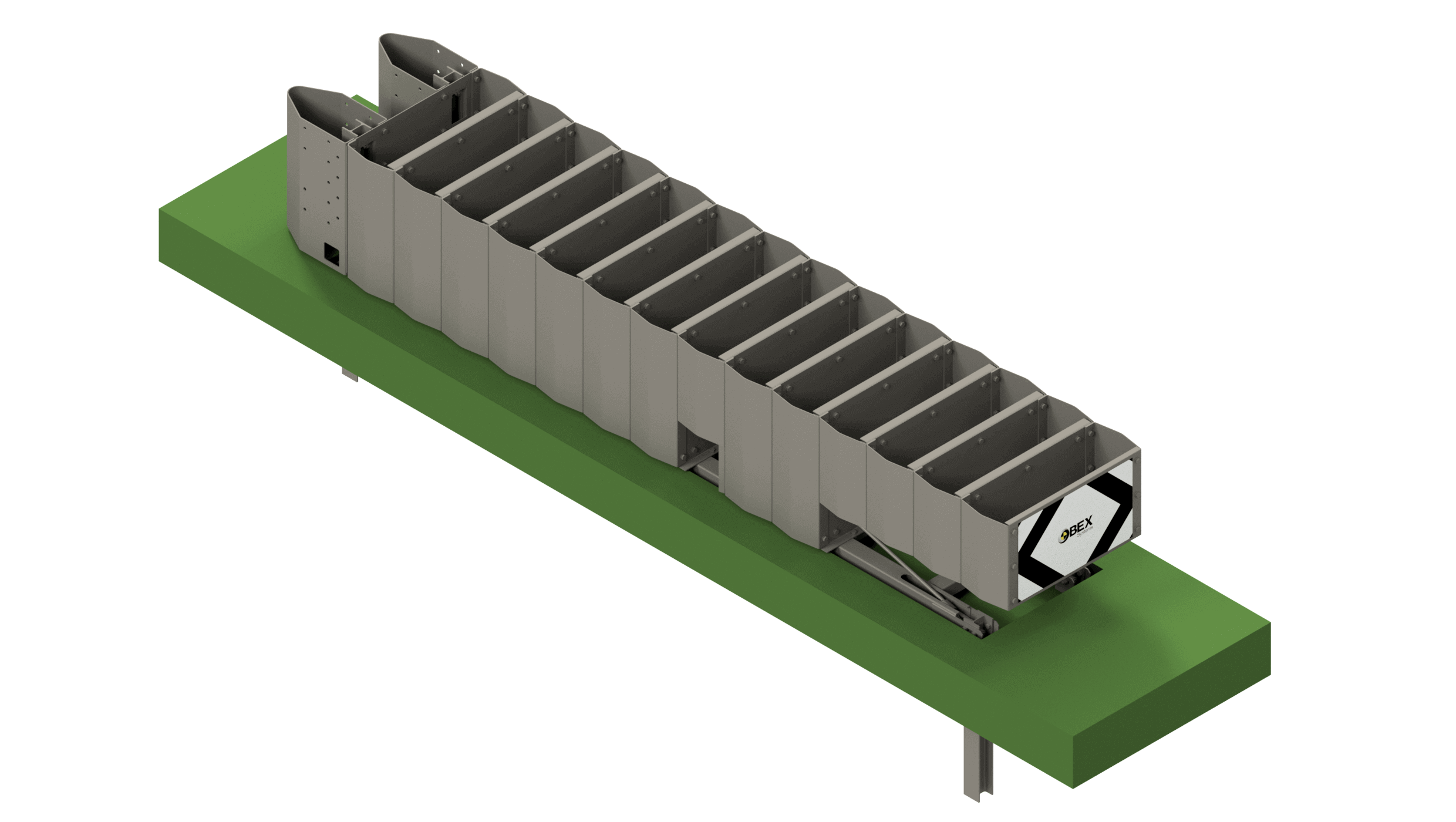

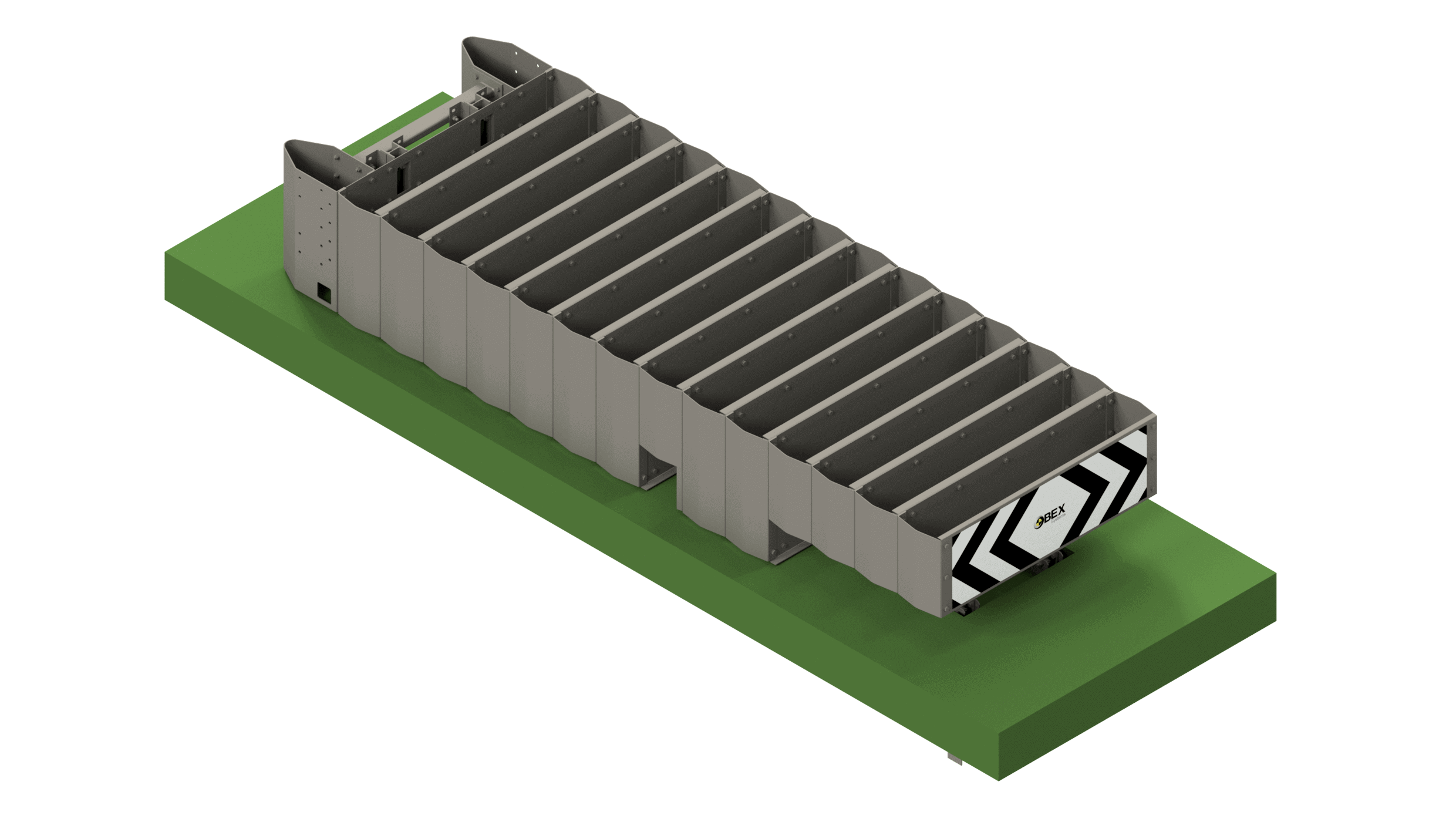

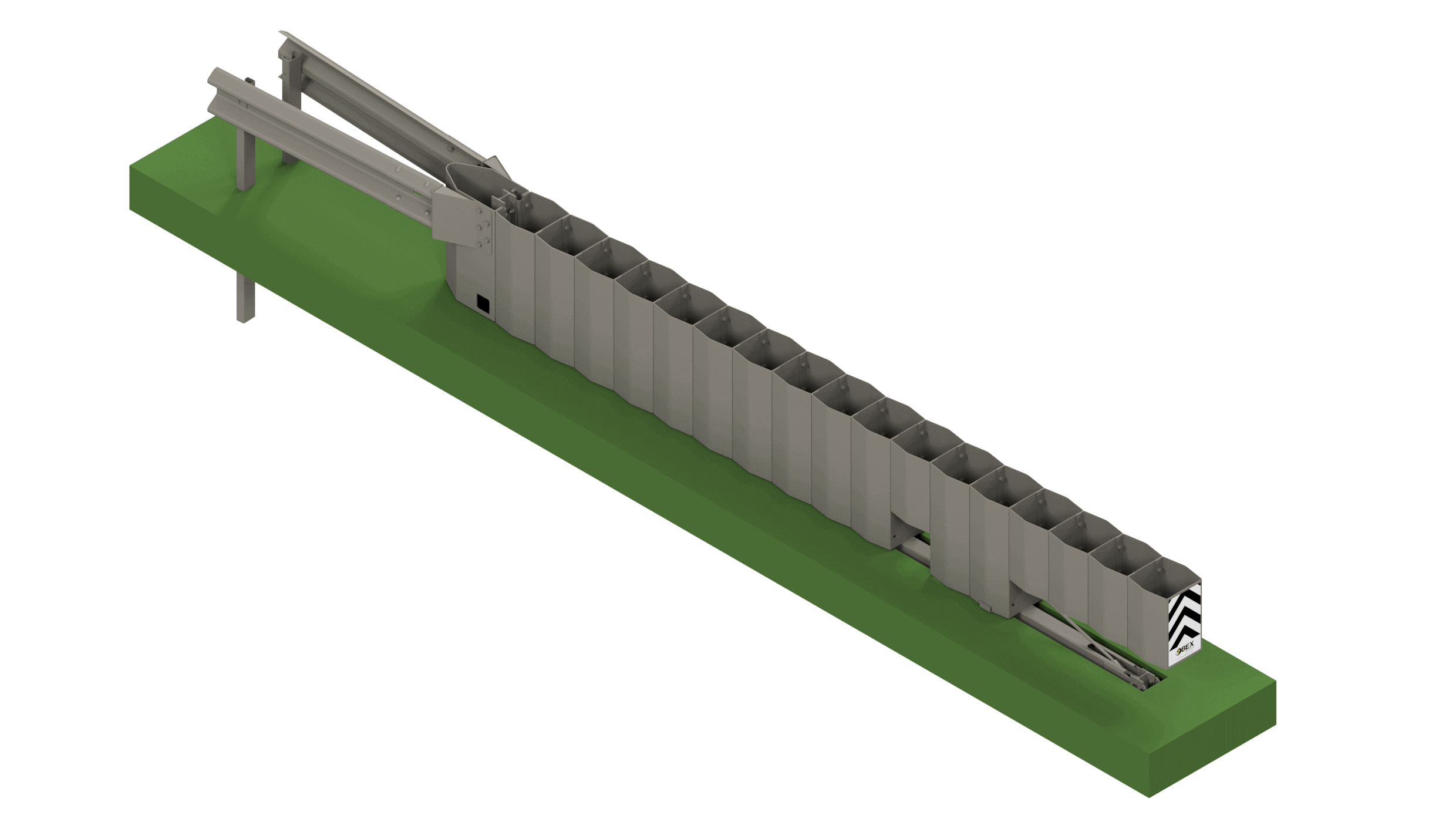

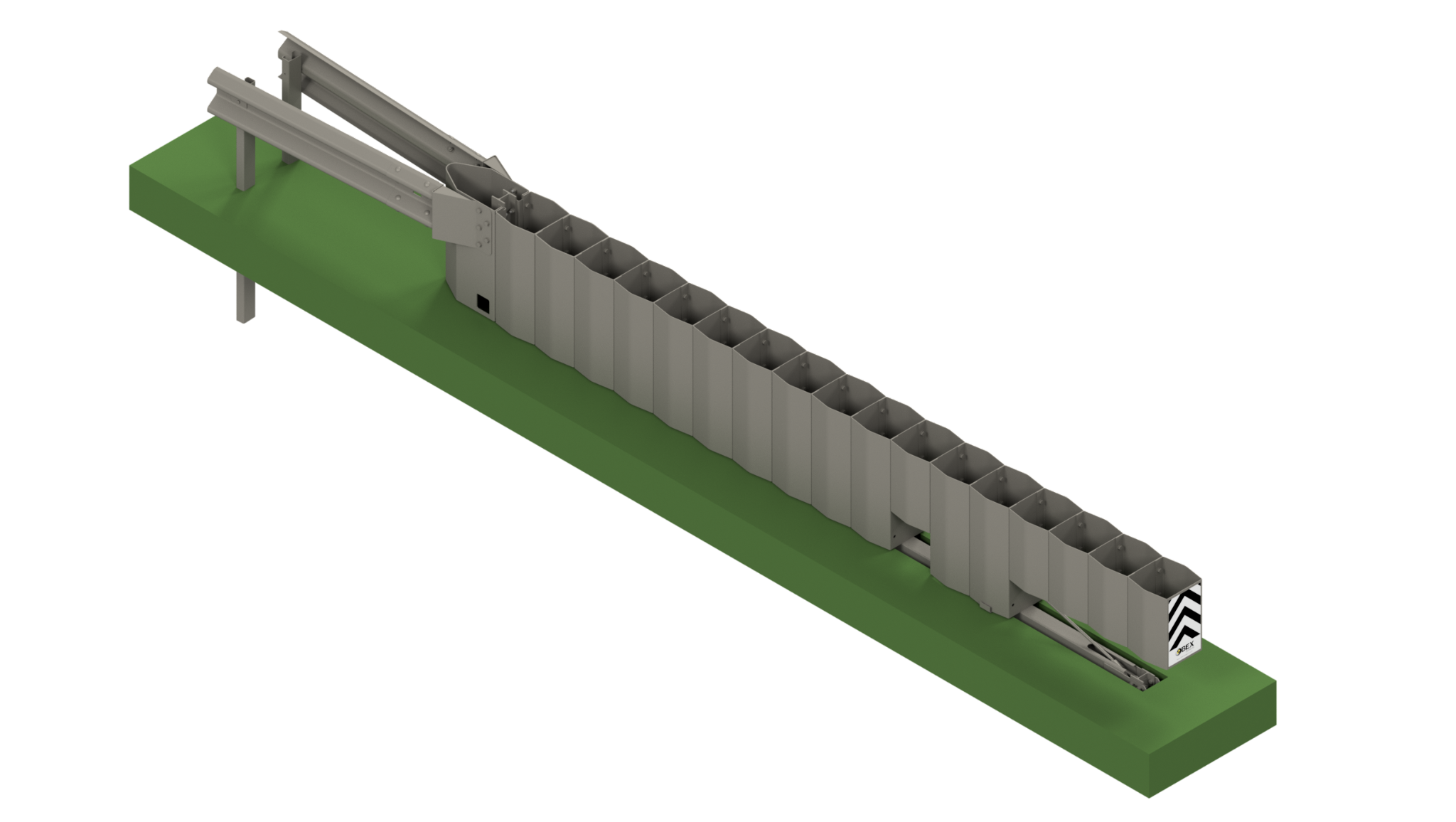

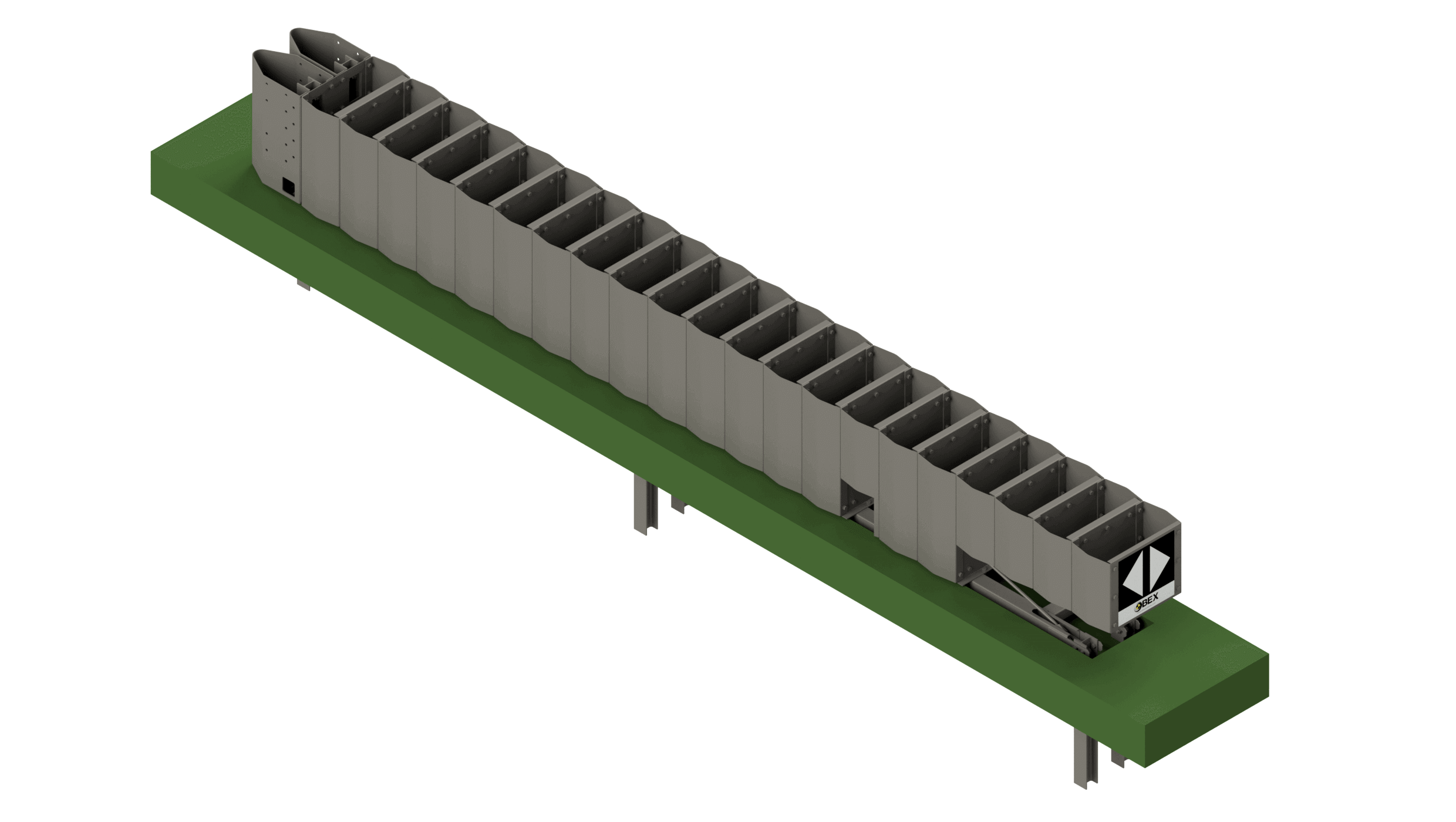

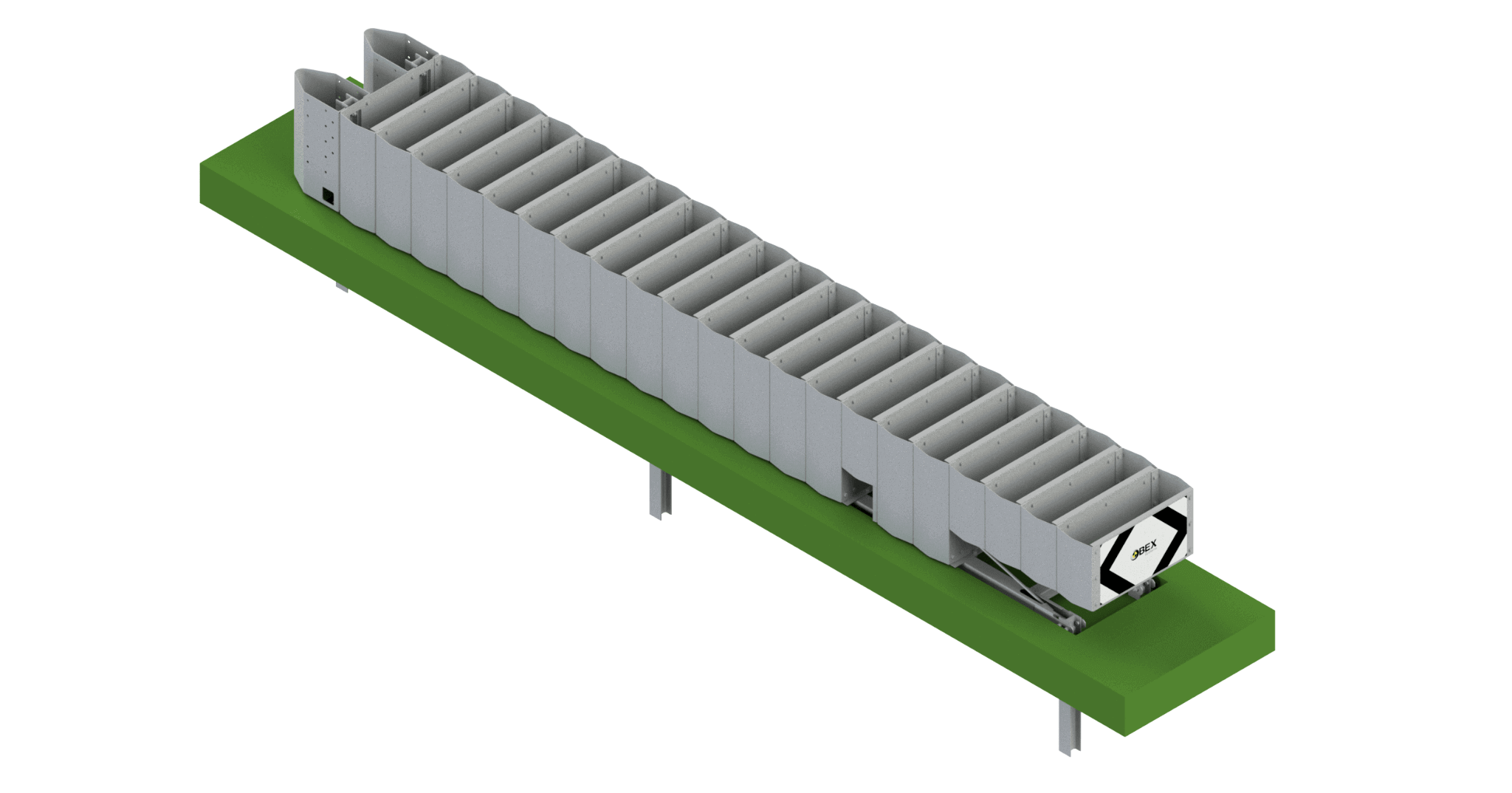

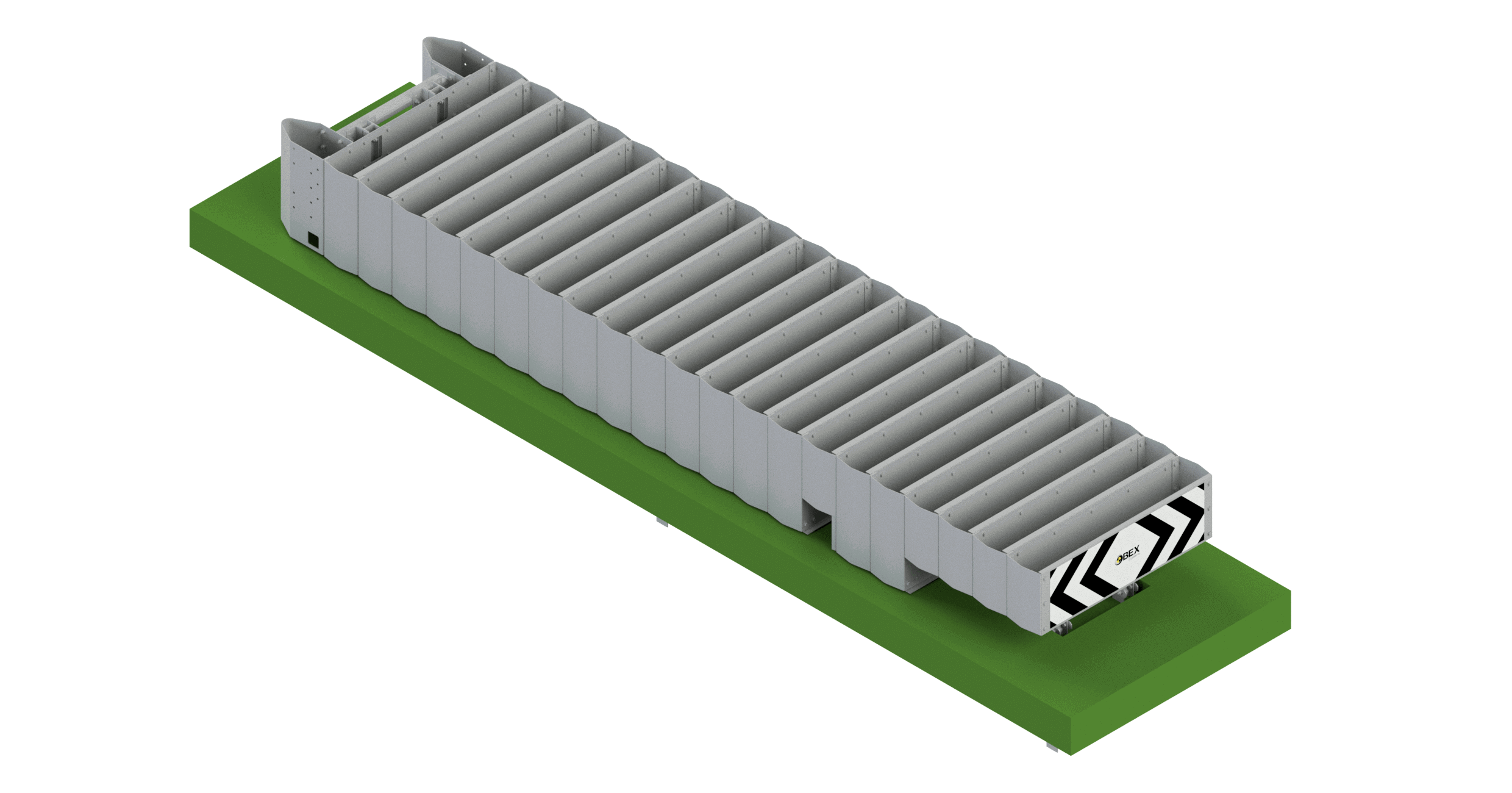

This positioning variability affects the chosen solution, since the crash cushions and barrier terminals can be obtained in families where, for the same system, there are several solutions in terms of widths and even inclinations of the walls, from 300mm to 2300mm wide.

These very brief notes regarding application criteria barely cover a few of the many doubtful aspects that are dealt with in much greater detail in a 40-minute webinar where, with many examples, photos and videos, we try to shed some light on the criteria that we are currently applying, To see this webinar access here.

Range of Impact Attenuators with CE marking from METALESA

By way of conclusion, we would like to point out that private companies are systematically developing new and better systems that optimize road safety conditions on our roads. But none of these will not go very far if it is not led by legal and regulatory tools that define how to use VCS efficiently and homogeneously. At Metalesa we have extensive experience in application criteria for these systems after multiple projects, and in case of doubt, we will be happy to advise and guide any technician and professional to shed some light on this world of vehicle containment systems.