The main characteristic defining the performance of any VCS is its ability to prevent a vehicle that leaves the road from reaching an obstacle, a different level or risk element that it is intended to protect against.

Since 1 January 2011, all vehicle containment systems installed on roads in the European Union must be certified under a new harmonised Standard, UNE EN 1317. This text has greatly contributed to the road safety sector as it homogenises the testing methodology and acceptance criteria of VCS across the whole continent.

The ultimate aim of the Standard is to guarantee that any VCS installed:

Ensures that the system contains the vehicle (without penetrating the system or overturning) – Containment level

Ensures that the vehicle will not fall down a slope, nor the vehicle or system impact any obstacle – System deformation

Slow downs deceleration to minimise injury to its occupants – Impact Severity

Guarantees that the vehicle will not cross into other lanes – Redirection

The performance of a containment system against vehicle impact essentially depends on the geometric and mechanical characteristics of the system’s individual constituent elements and assembly, as well as the type of foundations used. These variables result in different containment systems, which are distinguished by the effects and consequences that a vehicle impact has on the vehicle, its occupants and the system itself

According to the result obtained in full-scale crash tests, the Standard allows the performance of the VCS to be classified through a series of technical parameters:

Indicates the ability of a VCS to withstand the load from a vehicle’s impact.

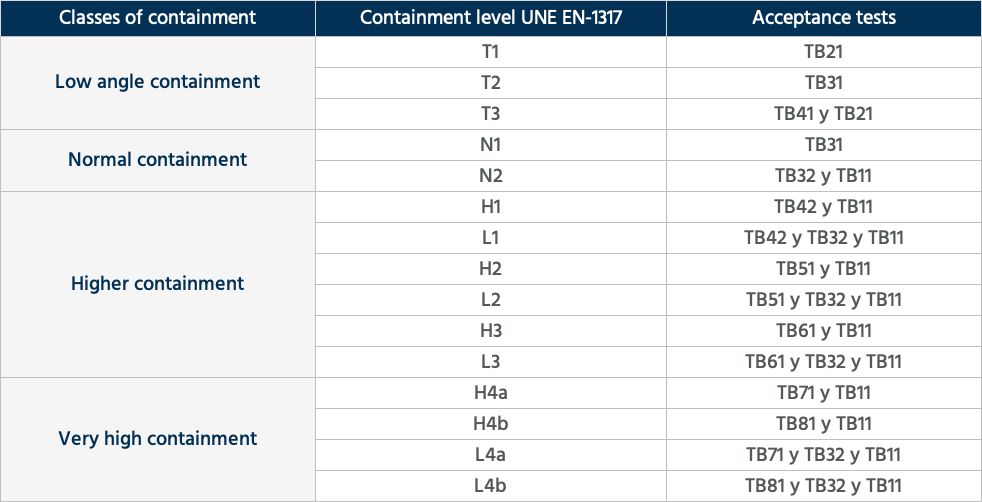

Selecting the containment level that a safety barrier to be installed on the end of a road must have will depend on the risk of accidents, in turn defined by the speed of the road and the average intensity of HGVs in each direction at the time of implementation. In line with the previous definition, UNE EN 1317 defines several containment levels. Each containment level is acquired from successfully passing one or more full-scale tests. The list of tests accrediting each level is shown in the following table:

UNE EN 1317 also defines the full-scale test conditions carried out in accredited laboratories, setting values for vehicle mass, speed at time of impact and the angle of impact against the barrier.

Once the containment level has been established, a complex system of laboratory-calibrated high-performance sensors and cameras allows the barrier’s performance in the tests to be defined using specific values of the following parameters.

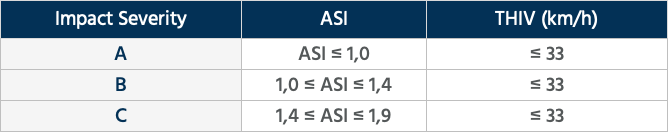

A vehicle impacting against a VCS carries obvious risks for its occupants. The severity of these risks inside the passenger compartment is determined by the impact severity level. This is calculated from the combination of deceleration (ASI) and head impact (THIV) values. Installing a VCS with an impact severity level of C is not permitted in Europe as this value presupposes an impact with a fatal outcome for the driver.

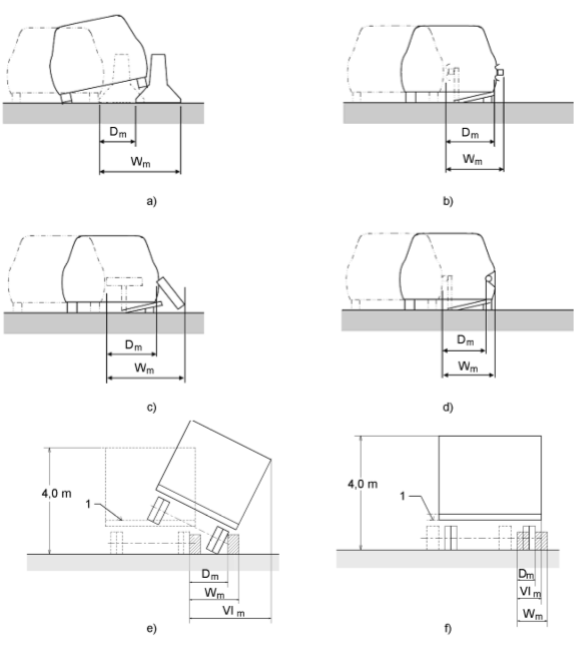

The performance of a VCS is characterised by the transverse displacement of the device during an impact. This is defined in the tests by means of dynamic deflection (D) and working width (W).

- Dynamic Deflection (D):: The maximum lateral dynamic displacement on the side of the VCS facing the traffic. It is measured in metres.

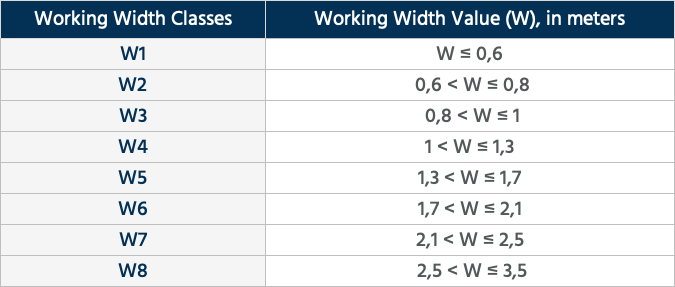

- Working Width (W): The distance between the side of the containment system closest to the flow of traffic before the impact and the furthest lateral position that reaches any essential part of the VCS during the crash. The Standard classifies this parameter from W1 to W8 depending on the metres of displacement.

- Vehicle Intrusion (VI): This is the maximum dynamic lateral displacement of the side of the barrier facing traffic without deforming. It is evaluated using photographs or high-speed video and considers a hypothetical load with width and length equal to that of the floor of the vehicle, and a total height of 4m. The Standard classifies this parameter from VI1 to VI5 depending on the metres of displacement.

The following image shows several possible lateral displacement situations, and how the three parameters are measured in each case. The value does not relate to the type of VCS but the difference between the initial and final position of each VCS element and/or the vehicle.

The Spanish Standardisation Association (UNE) is a private, multisectoral, non-profit agency appointed by the Ministry of Economy, Industry and Competitiveness as a national standardisation body.

European standards are implemented in the Technical Standardisation Committees (CTNs), managed by the technical services of UNE, the secretarial work of which is generally performed by an association or business federation in which the entire value chain of each sector is represented.

CTN 135 “Road signalling equipment” is the Technical Committee answerable to UNE, which is responsible for the standardisation of elements or equipment intended for signalling, safety, marking and traffic designed for road information, planning and safety (roads and urban roads), such as traffic signs, road markings, barriers, temporary signage, etc., all in their aspects of terminology and definitions, classification, characteristics, testing, design, etc., including supports and foundations.

In turn, these CTNs may have one or more subcommittees. In particular, SC1 is responsible for road safety barriers and SC6 for noise reducing devices.

METALESA is part of SC1 Safety Barriers in CTN 135, providing its experience and vision in all aspects of regulatory implementation.

CTN 135 is the Spanish transposition of CEN/TC 226 Road Equipment, which coordinates these same issues among the different national CTNs of the European Union Member States.

Standard UNE EN 1317 is, in turn, composed of several sections that have been published over the years as they have been agreed by the national standardisation committees through the coordination of the European technical committee.

The current sections are as follows:

- UNE EN 1317-1:2011 Road restraint systems. Part 1: General terminology and criteria for test methods.

- UNE EN 1317-2:2011 Road restraint systems. Part 2: Performance classes, impact test acceptance criteria and test methods for safety barriers including vehicle parapets.

- UNE EN 1317-3:2011 Road restraint systems. Part 3: Performance classes, impact test acceptance criteria and test methods for crash cushions.

- UNE EN 1317-5:2008+A2:2012 Road restraint systems. Part 5: Product requirements and evaluation of conformity for vehicle containment systems.

In addition, other sections are being analysed and discussed in different European forums. For example, UNE-ENV 1317-4:2002 dealing with performance classes, impact test acceptance criteria and test methods for safety barrier terminals and transitions. As this standard is not mandatory in Europe, some countries have taken a step forward with their own standards that apply exclusively within their borders to regulate the issue of safety barrier terminals and transitions. This is the case of France with its NF 058, a standard with which METALESA has certified its Transition between META13/16 and concrete barrier.